Thu, 05 Jun 2025 16:31:41 +0200

While there are traditional methods for cleaning it, none offer the precision, safety, and effectiveness that ultrasonic washers provide, especially when dealing with delicate or complex parts. Brass is a material found in numerous objects and components, but over time, it tends to darken and lose its characteristic shine. Fortunately, ultrasonic cleaning machines offer an effective and gentle solution to restore its original appearance without damaging the parts.

At DCM Ultrasonic, we design and manufacture specialized equipment for the professional cleaning of brass parts, restoring their original shine without damaging the surface or compromising their shape or functionality.

These bubbles collapse onto the surface of the piece, removing adherent dirt without damaging the base material. This is especially useful for:

Thanks to their versatility, DCM Ultrasonic ultrasonic cleaners can accurately clean all types of blackened brass objects, such as: industrial and mechanical components, electrical connectors and terminals, musical instruments (nozzles, valves, metal parts), plumbing and faucet parts, among others.

The process is completely safe for brass, and the ultrasound intensity, liquid temperature, and treatment time can be adjusted to suit the level of soiling or fragility of each piece.

Whether for a restoration workshop, a production plant, or a technical maintenance service, our ultrasonic cleaners adapt to your needs.

REQUEST INFORMATION ABOUT OUR BRASS CLEANING EQUIPMENT

Our equipment ranges from compact machines to high-capacity industrial equipment, constructed entirely of AISI 304 or 316 stainless steel, with optimized power, digital control systems, intuitive interfaces, and the option to include oil separators, filters, lids, or automatic cycles.

If you're looking for a solution that saves you time, improves your results, and maintains the integrity of your parts, our ultrasonic cleaners are the ideal tool. DCM Ultrasonic, ultrasonic cleaning technology for metal parts with impeccable results.

News

Ultrasonic cleaners for brass cleaning

05 June de 2025

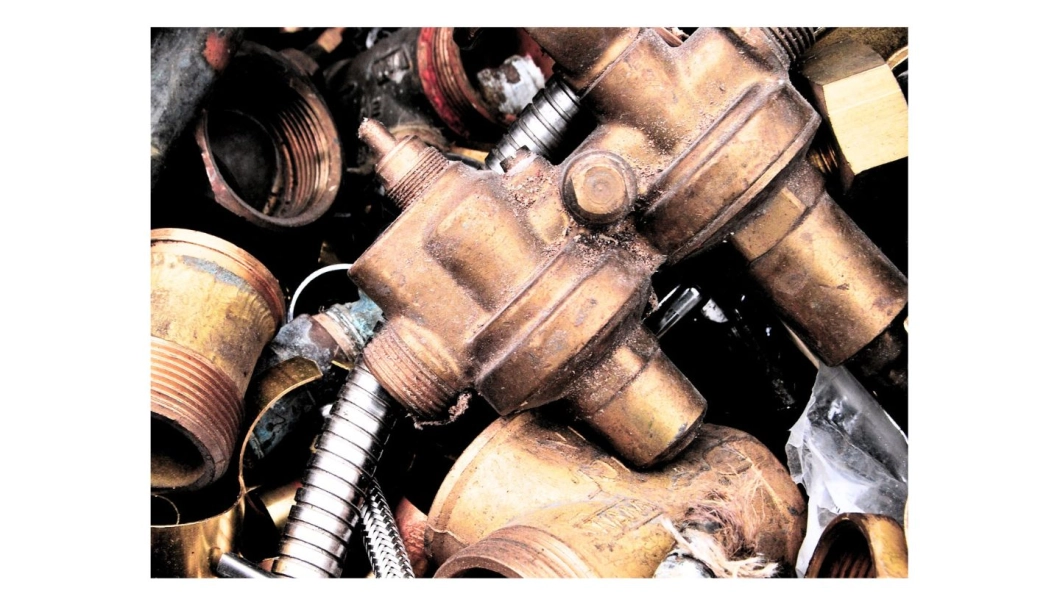

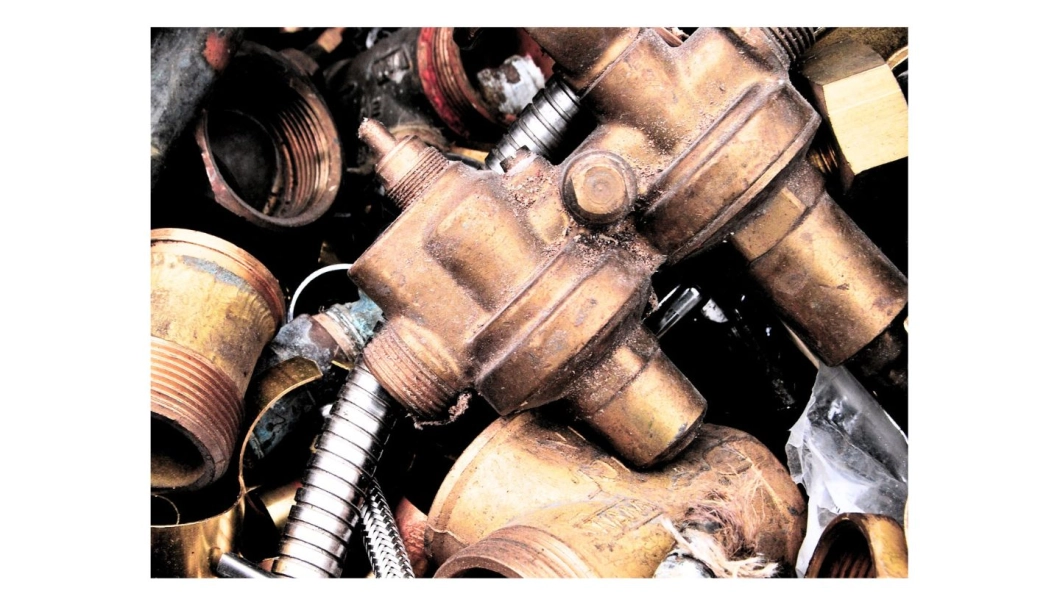

Brass, an alloy of copper and zinc, is widely used in sectors as diverse as plumbing, automotive, jewelry, industrial design, and the manufacturing of technical components. However, one of its most common problems is the darkening or blackening of the surface that occurs over time due to oxidation, dirt buildup, or exposure to contaminants.While there are traditional methods for cleaning it, none offer the precision, safety, and effectiveness that ultrasonic washers provide, especially when dealing with delicate or complex parts. Brass is a material found in numerous objects and components, but over time, it tends to darken and lose its characteristic shine. Fortunately, ultrasonic cleaning machines offer an effective and gentle solution to restore its original appearance without damaging the parts.

At DCM Ultrasonic, we design and manufacture specialized equipment for the professional cleaning of brass parts, restoring their original shine without damaging the surface or compromising their shape or functionality.

Cleaning Blackened Brass with Ultrasonic Washers

Ultrasonic cleaning machines are the most effective, fastest, and safest solution for removing dirt, oxides, and residue built up on brass. Instead of using brushes, abrasives, or harsh chemicals, the ultrasonic process works through high-frequency waves that generate millions of cavitation microbubbles in the cleaning fluid.These bubbles collapse onto the surface of the piece, removing adherent dirt without damaging the base material. This is especially useful for:

- Cleaning parts with complex shapes, holes, or crevices

- Removing embedded dirt evenly

- Restoring brass's original shine without mechanical polishing

- Reducing time and human effort in the process

What types of brass parts can be cleaned with ultrasound?

Thanks to their versatility, DCM Ultrasonic ultrasonic cleaners can accurately clean all types of blackened brass objects, such as: industrial and mechanical components, electrical connectors and terminals, musical instruments (nozzles, valves, metal parts), plumbing and faucet parts, among others.The process is completely safe for brass, and the ultrasound intensity, liquid temperature, and treatment time can be adjusted to suit the level of soiling or fragility of each piece.

Advantages of cleaning brass with our ultrasonic cleaners

At DCM Ultrasonic, we design our machines to deliver industrial performance even in the most demanding environments. These are some of the specific advantages of cleaning blackened brass with our equipment:- Deep cleaning without abrasion.

- Restores the original shine without chemical polishing.

- Reduced cleaning time and labor.

- Environmentally friendly process, without the need for harsh solvents.

- Consistent cleaning even on parts with complex geometry.

- Automation or in-line integration available.

- Available in desktop, standard, or custom-made formats.

Whether for a restoration workshop, a production plant, or a technical maintenance service, our ultrasonic cleaners adapt to your needs.

REQUEST INFORMATION ABOUT OUR BRASS CLEANING EQUIPMENT

Our equipment ranges from compact machines to high-capacity industrial equipment, constructed entirely of AISI 304 or 316 stainless steel, with optimized power, digital control systems, intuitive interfaces, and the option to include oil separators, filters, lids, or automatic cycles.

If you're looking for a solution that saves you time, improves your results, and maintains the integrity of your parts, our ultrasonic cleaners are the ideal tool. DCM Ultrasonic, ultrasonic cleaning technology for metal parts with impeccable results.