Mon, 09 Jun 2025 12:46:16 +0200

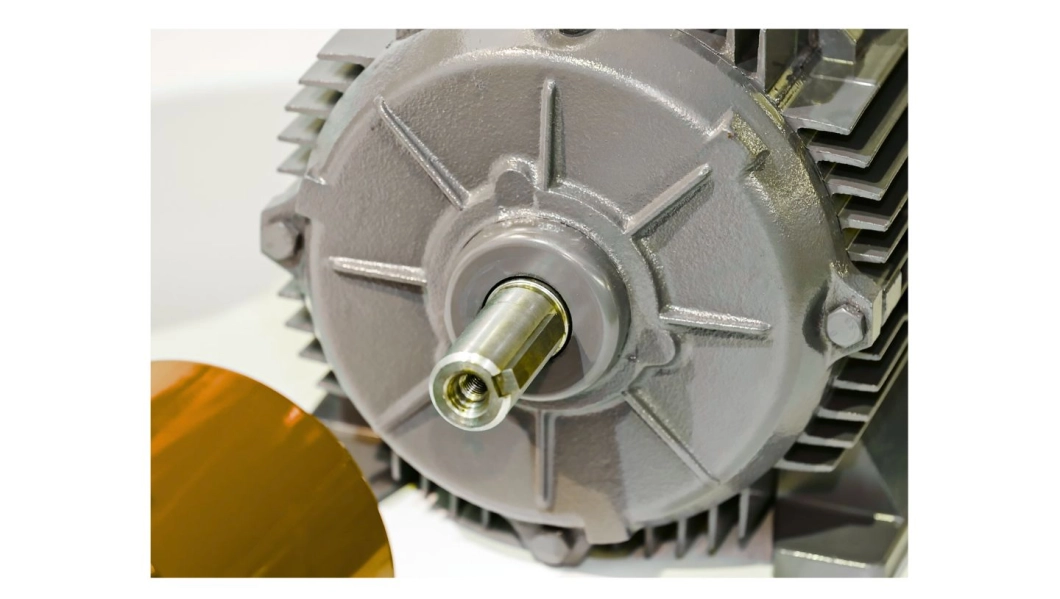

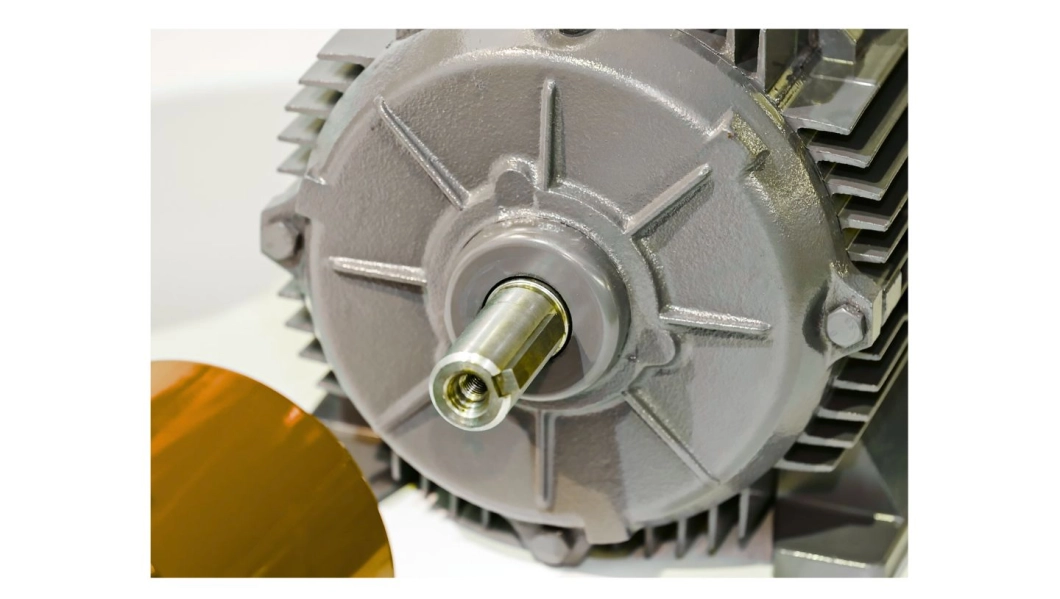

Marine propulsion systems are exposed to extreme conditions: salt water, combustion residue, carbonized oils, oxides, and metal particles. Over time, these contaminants accumulate on internal engine components and turbochargers, causing power loss, overheating, and mechanical failure.

Traditional cleaning often requires complex disassembly, harsh chemicals, or abrasive techniques that can prematurely wear surfaces. On the other hand, ultrasonic cleaning of marine turbochargers and marine engines offers a safe, thorough, and sustainable alternative. Our ultrasonic machines are designed for all types of cleaning, descaling, disinfection, and maintenance of all types of marine parts and components.

CLEANING MACHINES FOR THE NAUTICAL-NAVAL SECTOR

Another important advantage is the time savings; cleaning cycles are shorter and automated, allowing for greater productivity in naval workshops or shipyards. Added to this is improved reliability for engines and auxiliary systems, as effective cleaning prevents failures and extends the life of parts. All of this translates into more cost-effective maintenance, less downtime, and improved operational efficiency for vessels.

DISCOVER THE IDEAL CLEANING SOLUTION FOR NAVAL MAINTENANCE

We are committed to providing high-performance solutions for demanding environments. If you would like to learn more about our machines or request a test drive, please contact us. Your fleet deserves cleaning at the highest level of precision.

News

Cleaning of Marine Turbochargers and Marine Engines with Ultrasonic Cleaning Machines

09 June de 2025

Cleaning Nautical Turbos and Marine Engines with Ultrasonic Cleaning Machines. Maintaining critical components such as marine turbos and marine engines is essential to ensure efficient performance, reduce fuel consumption, and avoid costly downtime. One of the most effective and precise solutions for these tasks is the use of ultrasonic cleaning machines, a technology that has revolutionized the marine industry thanks to its ability to remove the most stubborn dirt without damaging the parts.Marine propulsion systems are exposed to extreme conditions: salt water, combustion residue, carbonized oils, oxides, and metal particles. Over time, these contaminants accumulate on internal engine components and turbochargers, causing power loss, overheating, and mechanical failure.

Traditional cleaning often requires complex disassembly, harsh chemicals, or abrasive techniques that can prematurely wear surfaces. On the other hand, ultrasonic cleaning of marine turbochargers and marine engines offers a safe, thorough, and sustainable alternative. Our ultrasonic machines are designed for all types of cleaning, descaling, disinfection, and maintenance of all types of marine parts and components.

How do ultrasounds work for cleaning marine turbochargers and nautical engines?

Ultrasonic cleaning is based on the generation of high-frequency sound waves within a fluid, usually water with a biodegradable detergent. These waves cause a physical phenomenon known as cavitation, which produces millions of microbubbles that collapse upon contact with dirt, grease, or carbon, removing scale even in hard-to-reach areas. This method:- Does not require excessive disassembly.

- Accesses internal channels, threads, fins, or hidden cavities.

- Respects the dimensional integrity of metal parts.

- Removes organic and inorganic residues and oxidation evenly.

CLEANING MACHINES FOR THE NAUTICAL-NAVAL SECTOR

Components or parts that can be cleaned in an ultrasonic bath

- Turbochargers: cleaning of casings, blades, bearings, and variable geometry without damaging the alloys.

- Cylinder heads and engine blocks: decarbonization of combustion chambers, cleaning of oil and cooling passages.

- Injectors and injection pumps: restoring operation by cleaning microscopic internal bores.

- Pistons and connecting rods: removal of carbon deposits, burnt oil residue, and varnish.

- Metal filters and control valves.

Advantages of Ultrasonic Cleaning for Marine and Naval Maintenance

Ultrasonic cleaning in the marine sector offers several key advantages that make it a highly efficient and sustainable technology. First, it allows for deep cleaning without damaging surfaces, which is essential for high-precision components such as turbos, injectors, and cylinder heads. Thanks to ultrasonic cavitation, carbon deposits, salt residue, burnt oil, and all types of scale are removed, even in hard-to-reach areas, such as internal ducts or complex geometries. Furthermore, this process drastically reduces the use of harsh chemicals, contributing to less pollution and a safer working environment.Another important advantage is the time savings; cleaning cycles are shorter and automated, allowing for greater productivity in naval workshops or shipyards. Added to this is improved reliability for engines and auxiliary systems, as effective cleaning prevents failures and extends the life of parts. All of this translates into more cost-effective maintenance, less downtime, and improved operational efficiency for vessels.

DISCOVER THE IDEAL CLEANING SOLUTION FOR NAVAL MAINTENANCE

Marine Sectors Most in Need of Cleaning and Maintenance

- Commercial shipping companies.

- Marine diesel engine maintenance companies.

- Shipyards specializing in repair and overhaul.

- Sports and recreational marine.

- Military vessels and patrol boats.

We are committed to providing high-performance solutions for demanding environments. If you would like to learn more about our machines or request a test drive, please contact us. Your fleet deserves cleaning at the highest level of precision.