Wed, 25 Jun 2025 13:27:49 +0200

At DCM Ultrasonic, we specialize in the cleaning of all types of industrial parts, materials, and components that require specialized, customized, and efficient maintenance. Adapted to all types of production processes and sectors.

Discover our cylinder cleaning machines

1. Total cleaning, even in inaccessible areas

Cylinders often have complex geometries, grooves, microcavities, or special coatings. Ultrasound penetrates all of these areas without leaving residue.

2. Non-aggressive process

Unlike blasting, brushing, or manual cleaning, ultrasound does not cause wear, which protects chrome plating, ceramic coatings, or precision engravings.

3. Compatibility with all materials

It can be used on steel, aluminum, brass, ceramic, hard chrome, engineering plastic, or composite cylinders.

4. Reduction in time and labor

The process is automated and much faster than manual methods. While the machine is working, the operator can perform other tasks.

5. Chemical savings

Biodegradable solutions with a low environmental impact are used. In addition, the system can integrate oil separators and filters that extend the life of the fluid.

6. Longer cylinder life

Effective removal of residues and contaminants reduces premature cylinder wear and prevents the progressive buildup of dirt.

3D model of our ultrasonic system for cylinder cleaning.

Highlighted features:

Discover our RL series

If your company works with cylinders that require regular and precise cleaning, the investment in a quality ultrasonic cleaning machine quickly pays for itself. At DCM Ultrasonic, we can help you find the perfect solution based on the type of cylinder, soiling, and workload.

News

Ultrasonic Cylinder Cleaning Machine

25 June de 2025

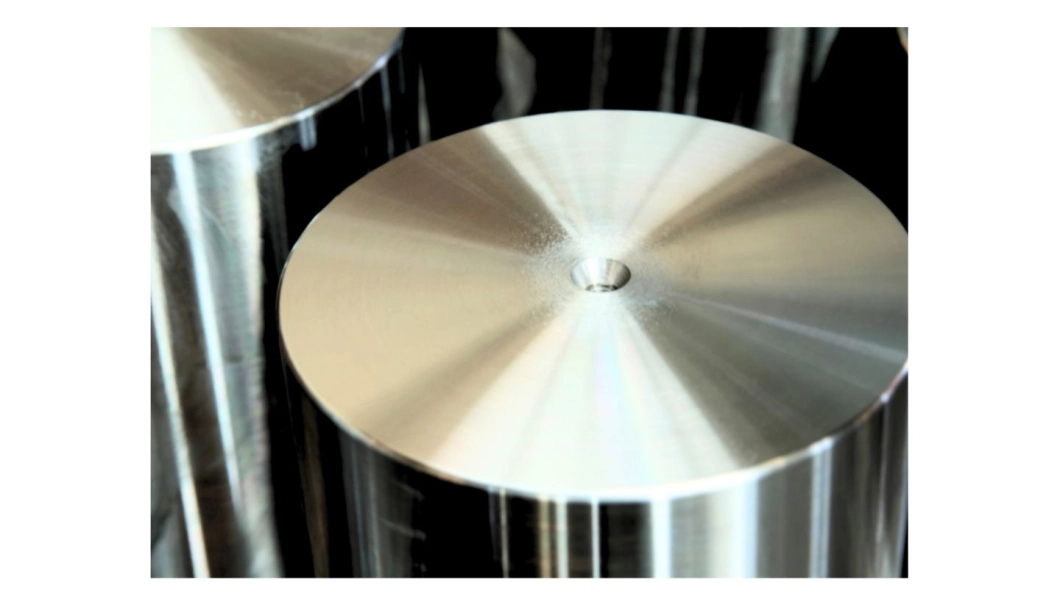

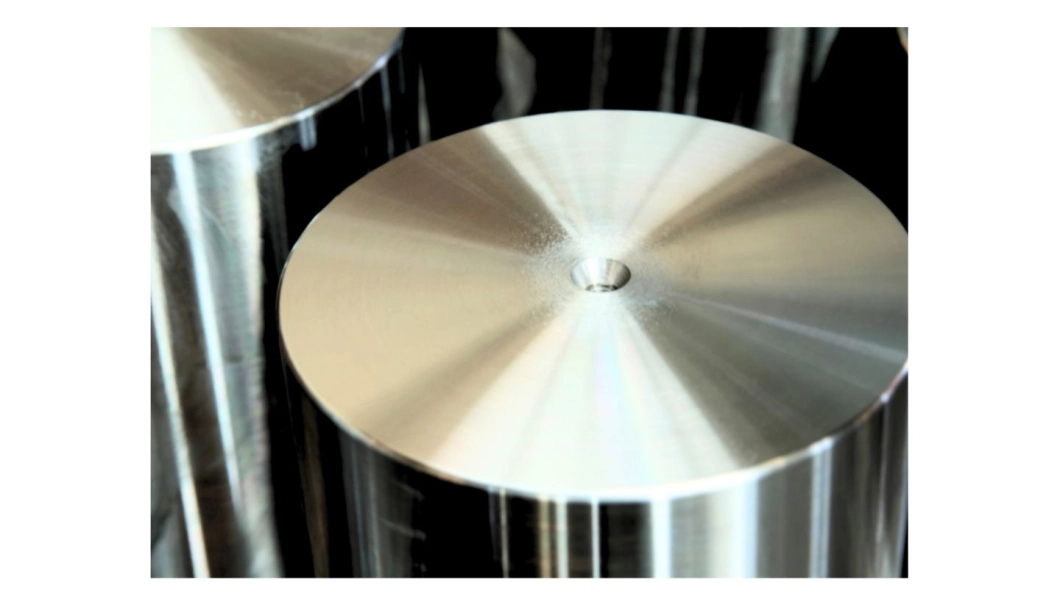

Cylinder cleaning is a critical process in multiple industrial sectors: printing, automotive, steel, textile, food, among many others. Accumulated residue, ink residue, oils, carbon deposits, resins, or metal shavings can affect the performance, quality of the final product, and the lifespan of these essential components. Ultrasonic cleaning has positioned itself as the most effective, safe, and environmentally friendly solution.At DCM Ultrasonic, we specialize in the cleaning of all types of industrial parts, materials, and components that require specialized, customized, and efficient maintenance. Adapted to all types of production processes and sectors.

The Importance of Cylinder Maintenance

Cylinders, whether hydraulic, pneumatic, anilox, chrome, printing, or laminating rolls, are in constant contact with fluids, inks, greases, or abrasive particles. If not cleaned properly:- Work accuracy is reduced.

- Production rejects and defects increase.

- Cylinder lifespan is shortened.

- Cross-contamination may occur in food or pharmaceutical lines.

Discover our cylinder cleaning machines

Advantages of Ultrasonic Cylinder Cleaning

1. Total cleaning, even in inaccessible areas

Cylinders often have complex geometries, grooves, microcavities, or special coatings. Ultrasound penetrates all of these areas without leaving residue.

2. Non-aggressive process

Unlike blasting, brushing, or manual cleaning, ultrasound does not cause wear, which protects chrome plating, ceramic coatings, or precision engravings.

3. Compatibility with all materials

It can be used on steel, aluminum, brass, ceramic, hard chrome, engineering plastic, or composite cylinders.

4. Reduction in time and labor

The process is automated and much faster than manual methods. While the machine is working, the operator can perform other tasks.

5. Chemical savings

Biodegradable solutions with a low environmental impact are used. In addition, the system can integrate oil separators and filters that extend the life of the fluid.

6. Longer cylinder life

Effective removal of residues and contaminants reduces premature cylinder wear and prevents the progressive buildup of dirt.

3D model of our ultrasonic system for cylinder cleaning.

Cylinder cleaning with our ultrasonic system

At DCM Ultrasonic, we develop specific machines for cylinder cleaning, such as our RL (Rotary Load) range. These machines are designed for cylindrical and rotating parts, allowing for uniform cleaning through controlled rotation during the ultrasonic process.Highlighted features:

- Controlled rotation with adjustable speed.

- Reinforced platforms for cylinders up to 500 kg.

- HMI/PLC control with the possibility of integration into lines.

- Synchronized digital ultrasonic generators (up to 40 kHz).

- Structure in AISI 304L or 316L stainless steel.

Discover our RL series

Recommendations for using an ultrasonic cylinder cleaning machine

- Select the right detergent: according to the type of contaminant (inks, greases, oxides, etc.).

- Control temperature and time: each material has its optimal temperature.

- Keep the liquid clean: with filters and automatic recycling.

- Adjust the ultrasonic frequency: 25kHz for heavy dirt, 40kHz for delicate dirt.

- Use rotary loading if the cylinder allows it: it improves cavitation and reduces dead zones.

If your company works with cylinders that require regular and precise cleaning, the investment in a quality ultrasonic cleaning machine quickly pays for itself. At DCM Ultrasonic, we can help you find the perfect solution based on the type of cylinder, soiling, and workload.