Fri, 26 Sep 2025 11:30:55 +0200

In this context, ultrasonic cleaning technology has established itself as the most effective solution compared to conventional washing, degreasing, and stripping methods. Its ability to reach internal cavities, complex geometries, and delicate surfaces makes it a standard for military and defense applications.

Discover our ultrasonic cleaning machines

Ultrasonic technology is based on cavitation: a physical phenomenon caused by high-frequency sound waves (20–80 kHz) transmitted in a liquid medium. These waves generate millions of microbubbles that collapse in a controlled manner on the surface of the components. The effect of this collapse produces:

Conventional cleaning methods such as sandblasting, chemical solvents, or manual cleaning are still used in the defense sector. Although effective in certain cases, they have significant limitations: sandblasting is abrasive and can damage delicate parts; Solvents are toxic, expensive, and harmful to sensitive materials; and manual cleaning is slow, inconsistent, and limited in its scope to internal geometries. These factors generate higher costs, environmental risks, and less reliable results.

Faced with these limitations, ultrasonic cleaning is positioned as an advanced alternative. Its cavitation action guarantees deep and uniform cleaning even in cavities and hard-to-reach areas, eliminating both physical and microbiological contaminants. Furthermore, it drastically reduces the use of aggressive chemicals, improves process sustainability, and offers automatable, traceable, and repeatable cycles. All of this translates into time savings, reduced operating costs, and greater safety in the maintenance of strategic components for the defense industry.

Request more information

Air Forces: Cleaning jet engine injectors to ensure optimal combustion.

Light and heavy weapons: decontamination of gunpowder residue and heavy metals in barrels.

Military shipyards: treatment of valves and hydraulic systems on warships.

Defense laboratories: sanitization of highly sensitive electronic devices.

Cleaning with ultrasonic machines in the defense industry has become a technological cornerstone to ensure the reliability, safety, and durability of critical equipment. Its ability to achieve levels of precision impossible with conventional methods, along with its respect for materials and the environment, make this technology irreplaceable today.

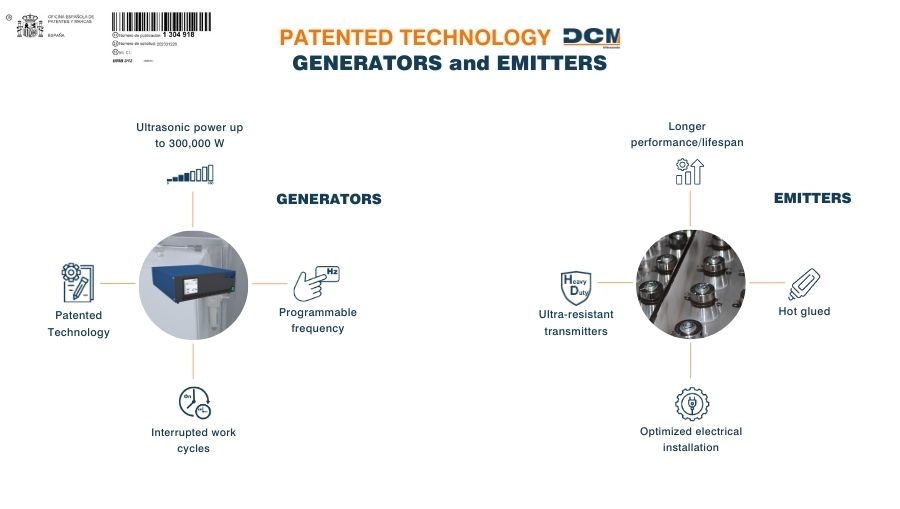

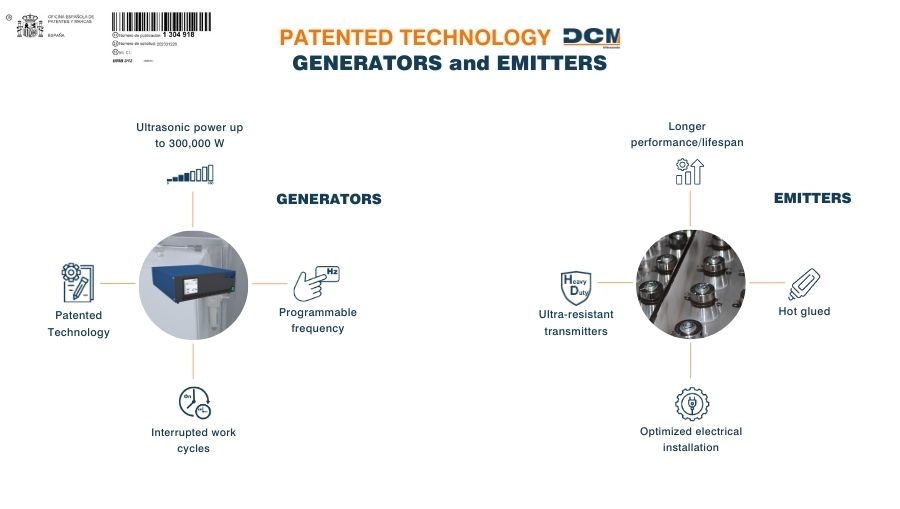

In a sector where operational efficiency and national security are at stake, the adoption of ultrasonic cleaning systems represents not only a competitive advantage but a strategic necessity. DCM Ultrasonic offers specialized ultrasonic cleaning machine solutions designed to meet the demands of the defense sector, from laboratories to shipyards and military bases, with robust, precise, and highly efficient technology.

News

Ultrasonic cleaning for the arms and defense industry

26 September de 2025

Cleaning in the defense and arms industries represents one of the greatest technical challenges due to the complexity of the equipment, the sensitivity of the materials, and the strict quality regulations that govern the sector. From weapons components to navigation systems, electronic components, and precision mechanical parts, the ability to ensure complete and safe decontamination is critical for both operational reliability and user safety.In this context, ultrasonic cleaning technology has established itself as the most effective solution compared to conventional washing, degreasing, and stripping methods. Its ability to reach internal cavities, complex geometries, and delicate surfaces makes it a standard for military and defense applications.

Specific Cleaning Needs in the Defense and Arms Industry

Companies and organizations in the defense sector require a cleaning system that meets highly demanding criteria:- Total removal of residues: grease, oil, carbon, oxides, gunpowder residue, explosives, or microscopic metal particles.

- Protection of sensitive materials: titanium alloys, aeronautical aluminum, treated steels, technical ceramics, and high-performance polymers.

- Compatibility with electronic components: circuit boards, sensors, connectors, and communication equipment.

- Regulatory compliance: processes must comply with international defense standards (MIL-SPEC, ISO, NATO).

- Reduction in downtime: cleaning must be fast and repeatable to ensure the continued operation of equipment and fleets.

Discover our ultrasonic cleaning machines

Ultrasonic cleaning operating principle

Ultrasonic technology is based on cavitation: a physical phenomenon caused by high-frequency sound waves (20–80 kHz) transmitted in a liquid medium. These waves generate millions of microbubbles that collapse in a controlled manner on the surface of the components. The effect of this collapse produces:

- High-energy microjets that release contaminants without damaging the base material.

- Penetration into microchannels, grooves, and cavities inaccessible to brushes or pressurized water jets.

- Cleaning uniformity, ensuring identical results on all parts in the batch, even with complex geometries.

Types of parts and materials that benefit from ultrasonic cleaning in defense

In the field of cleaning in the defense industry, ultrasonic baths are applied to a wide variety of critical components:

Mechanical and weapons components

- Pistols, rifles, machine guns, and automatic cannons.

- Buttstocks, bolts, and firing mechanisms.

- Missile and projectile casings.

- Hydraulic and pneumatic systems of military vehicles.

Engines and propulsion systems

- Military aircraft turbines.

- Fuel injectors and combustion chambers.

- Precision bearings, bushings, and gears.

Electronic and optical components

- Electronic circuit boards, sensors, radars, and communications equipment.

- Night vision systems, precision lenses and optics.

- Electrical connectors and optical fibers.

Specialty materials

- Lightweight titanium and aeronautical aluminum alloys.

- Heat-treated stainless steels.

- Technical ceramics used in armor or sensors.

- High-strength polymers used in coatings and gaskets.

Cleaning methods in the arms and defense industry

Conventional cleaning methods such as sandblasting, chemical solvents, or manual cleaning are still used in the defense sector. Although effective in certain cases, they have significant limitations: sandblasting is abrasive and can damage delicate parts; Solvents are toxic, expensive, and harmful to sensitive materials; and manual cleaning is slow, inconsistent, and limited in its scope to internal geometries. These factors generate higher costs, environmental risks, and less reliable results.

Faced with these limitations, ultrasonic cleaning is positioned as an advanced alternative. Its cavitation action guarantees deep and uniform cleaning even in cavities and hard-to-reach areas, eliminating both physical and microbiological contaminants. Furthermore, it drastically reduces the use of aggressive chemicals, improves process sustainability, and offers automatable, traceable, and repeatable cycles. All of this translates into time savings, reduced operating costs, and greater safety in the maintenance of strategic components for the defense industry.

Key Benefits of Ultrasonic Cleaning in the Defense and Arms Industry

- Preserving Part Integrity: Because it is non-abrasive, cavitation does not alter critical tolerances or surface finishes.

- Improving Operational Safety: Complete waste elimination ensures that weapons, engines, and electronic systems operate flawlessly.

- Reducing Maintenance Costs: Minimizing the need for premature component replacement.

- Regulatory Compliance and Traceability: Allows for documentation and standardization of processes according to defense regulations.

- Environmental Efficiency: Lower water, energy, and chemical consumption compared to conventional alternatives.

- Versatility: Adaptable to small parts such as microchips and large components such as turbines or armor.

Request more information

Application Cases Using Ultrasonic Machines

Air Forces: Cleaning jet engine injectors to ensure optimal combustion.

Light and heavy weapons: decontamination of gunpowder residue and heavy metals in barrels.

Military shipyards: treatment of valves and hydraulic systems on warships.

Defense laboratories: sanitization of highly sensitive electronic devices.

Cleaning with ultrasonic machines in the defense industry has become a technological cornerstone to ensure the reliability, safety, and durability of critical equipment. Its ability to achieve levels of precision impossible with conventional methods, along with its respect for materials and the environment, make this technology irreplaceable today.

In a sector where operational efficiency and national security are at stake, the adoption of ultrasonic cleaning systems represents not only a competitive advantage but a strategic necessity. DCM Ultrasonic offers specialized ultrasonic cleaning machine solutions designed to meet the demands of the defense sector, from laboratories to shipyards and military bases, with robust, precise, and highly efficient technology.