Mon, 10 Mar 2025 09:09:14 +0100

The UCM 1000DL LONG is designed to meet the specific cleaning needs of long, heavy industrial parts. Its main technical specifications include:

These features allow the machine to handle large and heavy parts, ensuring efficient and uniform cleaning across the entire surface. With this ultrasonic cleaning machine you ensure efficient and uniform cleaning on long parts that require cleaning and maintenance for proper operation.

SEE UCM 1000DL LONG CLEANING MACHINE

Ultrasonic cleaning technology offers multiple advantages compared to traditional methods:

1. Effectiveness in Removing Contaminants

Ultrasonic waves generate cavitation, creating microbubbles that implode and effectively remove contaminants such as oils, grease, oxides and machining residues adhering to the surfaces of the parts.

2. Access to Hard-to-Reach Areas

The ability of microbubbles to penetrate internal cavities, grooves and complex areas ensures complete cleaning, even in complicated geometries that would be inaccessible with conventional methods.

3. Uniformity in Cleaning

Ultrasonic waves ensure homogeneous cleaning in all areas of the part, eliminating the possibility of untreated areas and guaranteeing consistent results.

4. Reduced Chemical Use

The efficiency of cavitation allows for effective cleaning using fewer chemicals and in lower concentrations, reducing environmental impact and improving workplace safety.

5. Time and Cost Savings

The speed and efficiency of ultrasonic cleaning reduces the time required to clean objects compared to manual methods, increasing productivity and reducing operating costs.

The UCM 1000DL LONG is specifically designed for cleaning long and complex industrial parts. Its applications include:

1. Flat or Elongated Heat Exchangers

Efficient cleaning of heat exchangers is crucial to maintaining their performance and prolonging their life. The UCM 1000DL LONG removes deposits and contaminants that can affect heat transfer and system efficiency.

2. Pipes and Profiles

Long pipes and profiles, used in various industries, can accumulate residue and obstructions. The machine guarantees thorough cleaning, ensuring proper fluid flow and structural integrity.

3. Long Machining

Long machined parts require precise cleaning to remove machining residue and ensure proper operation. The UCM 1000DL LONG offers an effective solution to these needs.

4. Shafts, Cardan Shafts and Transmission Shafts

These components are essential in power transmission systems and require meticulous cleaning to ensure their performance and durability. The machine provides deep cleaning, removing contaminants that could cause wear or failure.

REQUEST MORE INFORMATION FOR PARTS CLEANING

The UCM 1000DL LONG incorporates several innovations that optimize the cleaning process:

Synchronized Digital Generator

This system ensures that all ultrasonic emitters work in a synchronized manner, avoiding the appearance of destructive waves in the bath that could reduce the performance of the equipment.

Double-Layer Thermoacoustic Insulation

The double-layer thermoacoustic insulation ensures that the sound pressure level remains below 78 dB, allowing the use of the equipment without requiring hearing protection. In addition, the thermal insulation preserves the temperature of the tank for several hours without significant losses, optimizing energy efficiency and reducing operating costs by minimizing the need to activate electric heating to maintain the desired temperature.

Dynamic and Static Load

The ultrasonic cleaning machine is designed to withstand static loads of up to 1,050 kg and dynamic loads of 525 kg, allowing the treatment of heavy parts without compromising the safety or efficiency of the cleaning process. This capability is crucial for industries that handle large and heavy components, such as petrochemical, railway, automotive and aerospace.

1. What type of parts can be cleaned with the UCM 1000DL LONG?

It is designed to clean long and bulky parts such as heat exchangers, pipes, shafts, cardan shafts, drive shafts and long machinings.

2. Is it compatible with all types of materials?

Yes, ultrasonic cleaning is safe for a wide variety of materials, including stainless steel, aluminum, copper and chemical-resistant plastics.

3. What cleaning solutions should be used?

Depending on the type of contaminant, alkaline, neutral or acidic solutions can be used. The choice of detergent should be made based on the type of contamination and the material of the part.

4. How long does a cleaning cycle take?

Cleaning time varies depending on the degree of contamination and the type of part, but in general, an ultrasonic cycle can last between 10 and 30 minutes.

5. How much does ultrasonic cleaning reduce chemical use?

Compared to traditional methods, chemical consumption can be reduced by up to 80%, which means less environmental impact and less expenditure on inputs.

6. What is the difference between the UCM 1000DL LONG and other DCM Ultrasonic models?

This model is optimized for large and long parts, offering a high-capacity tank and a special configuration for heavy loads, unlike other models designed for smaller components.

7. Does it require special installation?

No, the machine is delivered ready to operate and only requires a suitable electrical connection and the addition of the corresponding cleaning liquid.

8. How is operator safety guaranteed?

The UCM 1000DL LONG has thermo-acoustic insulation, digital controls and safety systems that protect the operator and ensure safe use.

9. What maintenance does the machine require?

Maintenance is minimal, but it is recommended to clean the tank regularly, check the digital generator and monitor the status of the cleaning liquid.

10. Which industries can benefit from this technology?

Industries such as petrochemical, railway, aerospace, automotive and mechanical component manufacturing find in the UCM 1000DL LONG an effective solution for cleaning critical parts.

The UCM 1000DL LONG ultrasonic cleaning machine from DCM Ultrasonic offers an efficient, sustainable and highly effective solution for large and long parts. Its innovative design, combined with advanced ultrasonic power and an optimized charging system, guarantees impeccable cleaning, reduced operating costs and minimal environmental impact.

If you are looking for a professional solution for cleaning flat heat exchangers, pipes, cardan shafts, shafts and other long components, the UCM 1000DL LONG is the ideal choice.

News

Long ultrasonic cleaner

10 March de 2025

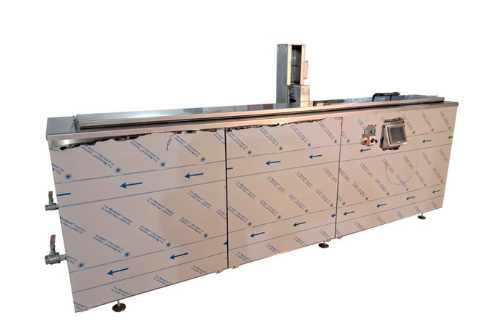

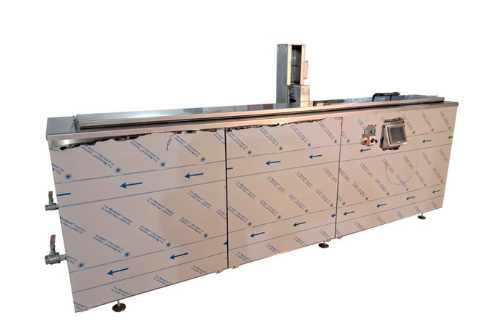

Ultrasonic cleaners has revolutionized the industry by offering efficient and precise solutions for removing contaminants from complex and large parts. The UCM 1000DL LONG ultrasonic cleaner, developed by DCM Ultrasonic, stands out as a machine specialized in cleaning long industrial components, such as flat or elongated heat exchangers, pipes, profiles, extensive machining, shafts, cardan shafts and transmission shafts.Ultrasonic cleaner

Technical Features - UCM 1000DL LONGThe UCM 1000DL LONG is designed to meet the specific cleaning needs of long, heavy industrial parts. Its main technical specifications include:

- Ultrasonic power: 8,000 W

- Heating power: 15,000 W

- Tank capacity: 1,050 liters

- Internal dimensions (LxWxH): 3,500 x 500 x 600 mm

- Useful dimensions (LxWxH): 3,450 x 450 x 450 mm

- External dimensions (LxWxH): 4,200 x 950 x 1,700 mm

- Maximum dynamic load: 525 kg

- Maximum static load: 1,050 kg

These features allow the machine to handle large and heavy parts, ensuring efficient and uniform cleaning across the entire surface. With this ultrasonic cleaning machine you ensure efficient and uniform cleaning on long parts that require cleaning and maintenance for proper operation.

SEE UCM 1000DL LONG CLEANING MACHINE

Benefits of our ultrasonic cleaner UCM 100DL LONG

Ultrasonic cleaning technology offers multiple advantages compared to traditional methods:1. Effectiveness in Removing Contaminants

Ultrasonic waves generate cavitation, creating microbubbles that implode and effectively remove contaminants such as oils, grease, oxides and machining residues adhering to the surfaces of the parts.

2. Access to Hard-to-Reach Areas

The ability of microbubbles to penetrate internal cavities, grooves and complex areas ensures complete cleaning, even in complicated geometries that would be inaccessible with conventional methods.

3. Uniformity in Cleaning

Ultrasonic waves ensure homogeneous cleaning in all areas of the part, eliminating the possibility of untreated areas and guaranteeing consistent results.

4. Reduced Chemical Use

The efficiency of cavitation allows for effective cleaning using fewer chemicals and in lower concentrations, reducing environmental impact and improving workplace safety.

5. Time and Cost Savings

The speed and efficiency of ultrasonic cleaning reduces the time required to clean objects compared to manual methods, increasing productivity and reducing operating costs.

UCM 1000DL LONG Applications

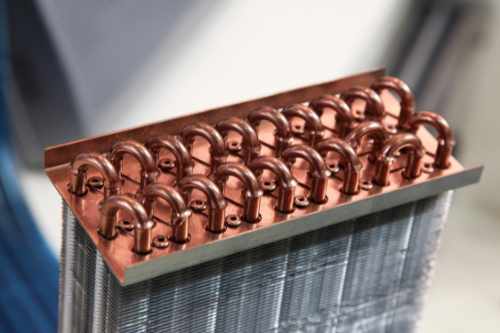

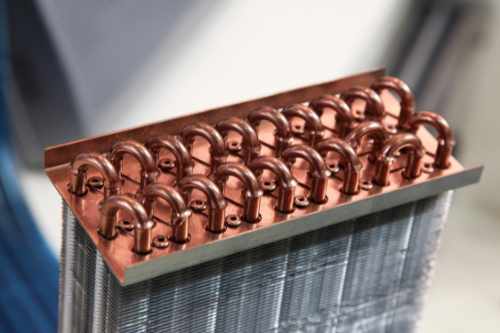

The UCM 1000DL LONG is specifically designed for cleaning long and complex industrial parts. Its applications include:1. Flat or Elongated Heat Exchangers

Efficient cleaning of heat exchangers is crucial to maintaining their performance and prolonging their life. The UCM 1000DL LONG removes deposits and contaminants that can affect heat transfer and system efficiency.

2. Pipes and Profiles

Long pipes and profiles, used in various industries, can accumulate residue and obstructions. The machine guarantees thorough cleaning, ensuring proper fluid flow and structural integrity.

3. Long Machining

Long machined parts require precise cleaning to remove machining residue and ensure proper operation. The UCM 1000DL LONG offers an effective solution to these needs.

4. Shafts, Cardan Shafts and Transmission Shafts

These components are essential in power transmission systems and require meticulous cleaning to ensure their performance and durability. The machine provides deep cleaning, removing contaminants that could cause wear or failure.

REQUEST MORE INFORMATION FOR PARTS CLEANING

Integrated Innovations and Technologies - Ultrasonic Cleaner

The UCM 1000DL LONG incorporates several innovations that optimize the cleaning process:Synchronized Digital Generator

This system ensures that all ultrasonic emitters work in a synchronized manner, avoiding the appearance of destructive waves in the bath that could reduce the performance of the equipment.

Double-Layer Thermoacoustic Insulation

The double-layer thermoacoustic insulation ensures that the sound pressure level remains below 78 dB, allowing the use of the equipment without requiring hearing protection. In addition, the thermal insulation preserves the temperature of the tank for several hours without significant losses, optimizing energy efficiency and reducing operating costs by minimizing the need to activate electric heating to maintain the desired temperature.

Dynamic and Static Load

The ultrasonic cleaning machine is designed to withstand static loads of up to 1,050 kg and dynamic loads of 525 kg, allowing the treatment of heavy parts without compromising the safety or efficiency of the cleaning process. This capability is crucial for industries that handle large and heavy components, such as petrochemical, railway, automotive and aerospace.

Manual vs. Ultrasonic Cleaning

Ultrasonic cleaning with the UCM 1000DL LONG ultrasonic cleaning machine has significant advantages over other cleaning methods used in the industry.- Manual Cleaning: Requires intensive use of chemicals, brushes and mechanical tools, which implies a greater investment in labor and a greater risk of cross contamination. In addition, manual cleaning can leave residues in hard-to-reach areas.

- Ultrasonic Cleaning: Guarantees complete removal of contaminants without the need for manual intervention, reaching every corner of the piece and ensuring a homogeneous and deep cleaning.

Frequently Asked Questions about the UCM 1000DL LONG - Ultrasonic Cleaner

1. What type of parts can be cleaned with the UCM 1000DL LONG?

It is designed to clean long and bulky parts such as heat exchangers, pipes, shafts, cardan shafts, drive shafts and long machinings.

2. Is it compatible with all types of materials?

Yes, ultrasonic cleaning is safe for a wide variety of materials, including stainless steel, aluminum, copper and chemical-resistant plastics.

3. What cleaning solutions should be used?

Depending on the type of contaminant, alkaline, neutral or acidic solutions can be used. The choice of detergent should be made based on the type of contamination and the material of the part.

4. How long does a cleaning cycle take?

Cleaning time varies depending on the degree of contamination and the type of part, but in general, an ultrasonic cycle can last between 10 and 30 minutes.

5. How much does ultrasonic cleaning reduce chemical use?

Compared to traditional methods, chemical consumption can be reduced by up to 80%, which means less environmental impact and less expenditure on inputs.

6. What is the difference between the UCM 1000DL LONG and other DCM Ultrasonic models?

This model is optimized for large and long parts, offering a high-capacity tank and a special configuration for heavy loads, unlike other models designed for smaller components.

7. Does it require special installation?

No, the machine is delivered ready to operate and only requires a suitable electrical connection and the addition of the corresponding cleaning liquid.

8. How is operator safety guaranteed?

The UCM 1000DL LONG has thermo-acoustic insulation, digital controls and safety systems that protect the operator and ensure safe use.

9. What maintenance does the machine require?

Maintenance is minimal, but it is recommended to clean the tank regularly, check the digital generator and monitor the status of the cleaning liquid.

10. Which industries can benefit from this technology?

Industries such as petrochemical, railway, aerospace, automotive and mechanical component manufacturing find in the UCM 1000DL LONG an effective solution for cleaning critical parts.

The UCM 1000DL LONG ultrasonic cleaning machine from DCM Ultrasonic offers an efficient, sustainable and highly effective solution for large and long parts. Its innovative design, combined with advanced ultrasonic power and an optimized charging system, guarantees impeccable cleaning, reduced operating costs and minimal environmental impact.

If you are looking for a professional solution for cleaning flat heat exchangers, pipes, cardan shafts, shafts and other long components, the UCM 1000DL LONG is the ideal choice.