Mon, 19 May 2025 16:28:16 +0200

Ultrasonic cleaning has established itself as the most advanced, effective, and cost-effective technological solution. Thanks to its ability to remove contaminants without damaging delicate surfaces, ultrasonic cleaning machines are revolutionizing maintenance in the graphic arts industry. This article takes an in-depth look at how this technology works, its benefits, and its specific application in cleaning printing rollers and tooling.

At DCM Ultrasonic, we offer fully automated solutions that simplify the removal of thick inks and paints, whether water-based, UV-based, or alcohol-based, from all types of removable components. Whether it's ink fountains, clichés, doctor blades, trays, or specialized cleaning of anilox rollers, sleeves, gravure, or ceramic rollers, we guarantee an efficient and hassle-free process.

In the graphic arts sector, DCM Ultrasonic offers a highly effective cleaning solution that significantly reduces both ink consumption and rejects due to quality issues. Our extensive experience in specialized cleaning of printing rollers and tools allows us to adapt the process to the specific needs of each type of material, ensuring careful and precise treatment.

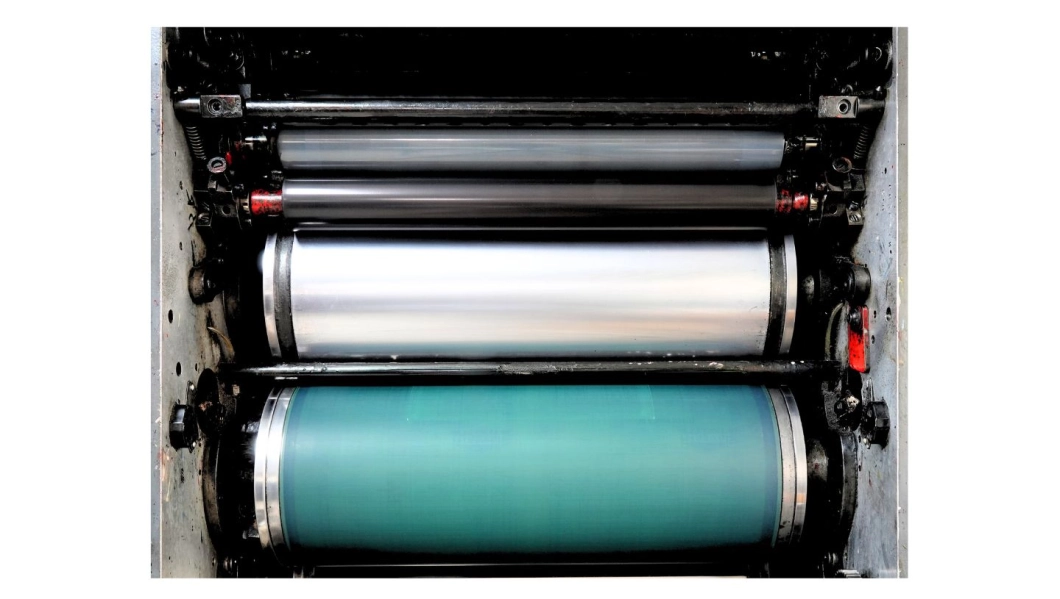

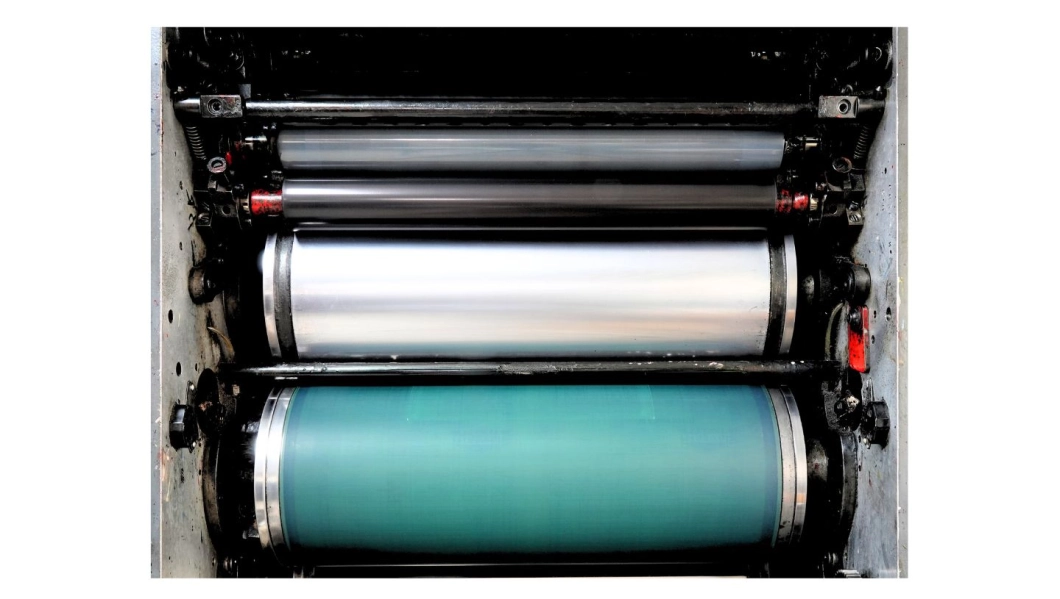

PRINTING ROLLER CLEANING MACHINE

This process effectively removes all types of contaminants, even in pores, grooves, or complex geometries, without the need for rubbing or applying harsh products. Ultrasonic cleaning is therefore a method:

During the process, energy is generated through the implosion of millions of microbubbles in a liquid medium, allowing for the rapid removal of adhering residues without the need for significant energy consumption. Furthermore, the ease of integration of these systems into industrial environments allows for maintaining operational continuity, optimizing workflows, and increasing the productivity of the treated components.

Implementing ultrasonic cleaning systems in the graphic arts industry offers numerous benefits:

1. Improved Print Quality

By completely removing all types of contaminants from rollers and tools, ink transfer is much more uniform and precise. This translates into a significant improvement in print quality and color fidelity.

2. Reduced Operating Costs

Regular maintenance with ultrasonic machines reduces the need for replacement parts, extends the life of rollers and other components, and minimizes the use of solvents and harsh chemicals. Additionally, automating the process reduces the need for labor.

3. Fast and Deep Cleaning

Ultrasonic machines can clean elements in just a few minutes that would take much longer with traditional methods. They also reach inaccessible areas without disassembling the part, which speeds up maintenance.

4. Environmental Protection

Ultrasonic cleaning uses water with a small proportion of biodegradable detergent, drastically reducing the use of volatile solvents that pollute and pose a risk to occupational health.

5. Greater Safety for Operators

By eliminating the need for harsh products and intensive manual handling, exposure to toxic substances and the risk of accidents or injuries from prolonged contact are minimized.

DISCOVER OUR MACHINE FOR CLEANING CYLINDERS AND GRAPHIC TOOLS

Cleaning printing rollers and graphic tools using ultrasonic cleaning machines represents a technical, economical, and sustainable solution for maintenance in the graphic arts industry. Its ability to remove ink, varnish, and residues without damaging delicate surfaces guarantees superior performance in every printing job.

Using DCM Ultrasonic means accessing multiple benefits. First, it allows for a significant reduction in ink consumption. Furthermore, it eliminates the high costs associated with manual labor and significantly speeds up changeover times for cylinders and other tooling. Another key point is that it eliminates the use of chemicals for effective cleaning. Thanks to its ability to completely empty the cylinder cells, it is possible to restore their original functional capacity, even in aged cylinders or those with clogged cells.

Adopting this technology not only improves productivity and final quality, but also reduces costs, extends the life of equipment, and promotes more sustainable practices. In an increasingly competitive and demanding environment, ultrasonic cleaning is positioned as a key tool for optimizing graphic processes.

News

Roller and Tool Cleaning for the Printing Industry

19 May de 2025

Cleaning printing rollers and tooling in the graphic arts industry. Efficient cleaning of printing rollers, plates, squeegees, and other tooling is critical to ensuring high print quality and extending equipment life. The accumulation of inks, varnishes, adhesives, and other residues on printing components compromises not only the finish of jobs but also the performance of the machinery.Ultrasonic cleaning has established itself as the most advanced, effective, and cost-effective technological solution. Thanks to its ability to remove contaminants without damaging delicate surfaces, ultrasonic cleaning machines are revolutionizing maintenance in the graphic arts industry. This article takes an in-depth look at how this technology works, its benefits, and its specific application in cleaning printing rollers and tooling.

At DCM Ultrasonic, we offer fully automated solutions that simplify the removal of thick inks and paints, whether water-based, UV-based, or alcohol-based, from all types of removable components. Whether it's ink fountains, clichés, doctor blades, trays, or specialized cleaning of anilox rollers, sleeves, gravure, or ceramic rollers, we guarantee an efficient and hassle-free process.

Importance of Roller and Tool Cleaning in the Graphic Arts

Printing rollers and other graphic components are in constant contact with inks, solvents, and emulsions. If not cleaned properly and regularly, these substances accumulate, causing problems such as:- Print defects (streaks, smears, or discolored areas).

- Variations in ink transfer.

- Increased wear on rollers and components.

- Frequent production downtime.

- High costs for spare parts and maintenance.

In the graphic arts sector, DCM Ultrasonic offers a highly effective cleaning solution that significantly reduces both ink consumption and rejects due to quality issues. Our extensive experience in specialized cleaning of printing rollers and tools allows us to adapt the process to the specific needs of each type of material, ensuring careful and precise treatment.

PRINTING ROLLER CLEANING MACHINE

Clean Printer Rollers and Graphic Tools with Ultrasonic

This process effectively removes all types of contaminants, even in pores, grooves, or complex geometries, without the need for rubbing or applying harsh products. Ultrasonic cleaning is therefore a method:

- Non-abrasive: does not damage or deform delicate surfaces such as rubber, chrome-plated steel, or aluminum.

- Efficient: completely removes ink, varnish, oil, grease, paper dust, and other residues.

- Fast: significantly reduces manual cleaning times.

- Automatable: can be easily integrated into production or maintenance lines.

During the process, energy is generated through the implosion of millions of microbubbles in a liquid medium, allowing for the rapid removal of adhering residues without the need for significant energy consumption. Furthermore, the ease of integration of these systems into industrial environments allows for maintaining operational continuity, optimizing workflows, and increasing the productivity of the treated components.

Advantages of Ultrasonic Cleaning in Graphic Arts

Implementing ultrasonic cleaning systems in the graphic arts industry offers numerous benefits:1. Improved Print Quality

By completely removing all types of contaminants from rollers and tools, ink transfer is much more uniform and precise. This translates into a significant improvement in print quality and color fidelity.

2. Reduced Operating Costs

Regular maintenance with ultrasonic machines reduces the need for replacement parts, extends the life of rollers and other components, and minimizes the use of solvents and harsh chemicals. Additionally, automating the process reduces the need for labor.

3. Fast and Deep Cleaning

Ultrasonic machines can clean elements in just a few minutes that would take much longer with traditional methods. They also reach inaccessible areas without disassembling the part, which speeds up maintenance.

4. Environmental Protection

Ultrasonic cleaning uses water with a small proportion of biodegradable detergent, drastically reducing the use of volatile solvents that pollute and pose a risk to occupational health.

5. Greater Safety for Operators

By eliminating the need for harsh products and intensive manual handling, exposure to toxic substances and the risk of accidents or injuries from prolonged contact are minimized.

DISCOVER OUR MACHINE FOR CLEANING CYLINDERS AND GRAPHIC TOOLS

DCM Ultrasonic takes care of your printing cylinders and tools in the graphic arts industry.

Cleaning printing rollers and graphic tools using ultrasonic cleaning machines represents a technical, economical, and sustainable solution for maintenance in the graphic arts industry. Its ability to remove ink, varnish, and residues without damaging delicate surfaces guarantees superior performance in every printing job.Using DCM Ultrasonic means accessing multiple benefits. First, it allows for a significant reduction in ink consumption. Furthermore, it eliminates the high costs associated with manual labor and significantly speeds up changeover times for cylinders and other tooling. Another key point is that it eliminates the use of chemicals for effective cleaning. Thanks to its ability to completely empty the cylinder cells, it is possible to restore their original functional capacity, even in aged cylinders or those with clogged cells.

Adopting this technology not only improves productivity and final quality, but also reduces costs, extends the life of equipment, and promotes more sustainable practices. In an increasingly competitive and demanding environment, ultrasonic cleaning is positioned as a key tool for optimizing graphic processes.