Wed, 25 Jun 2025 10:38:55 +0200

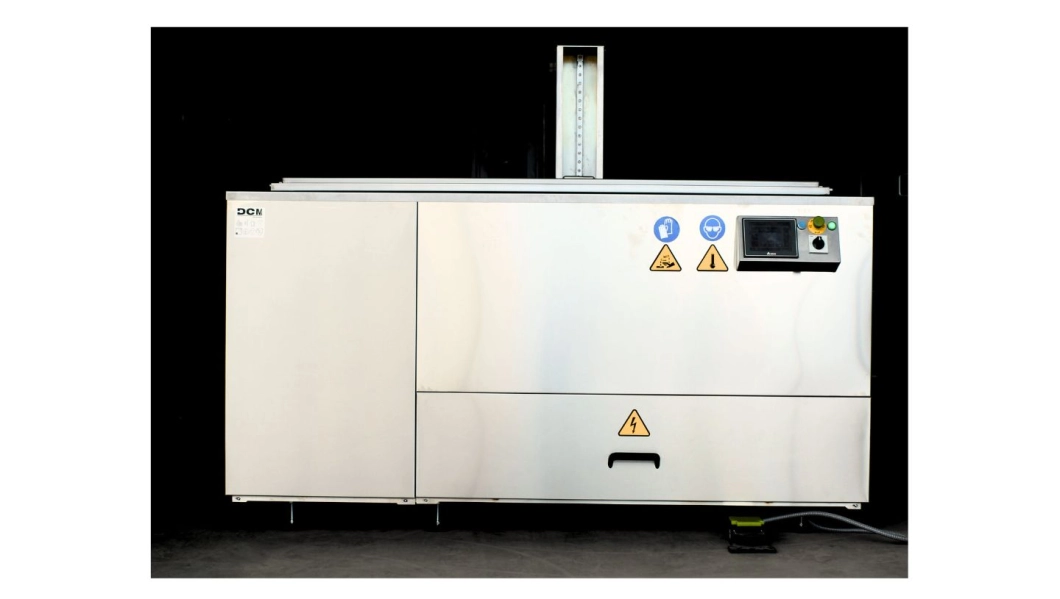

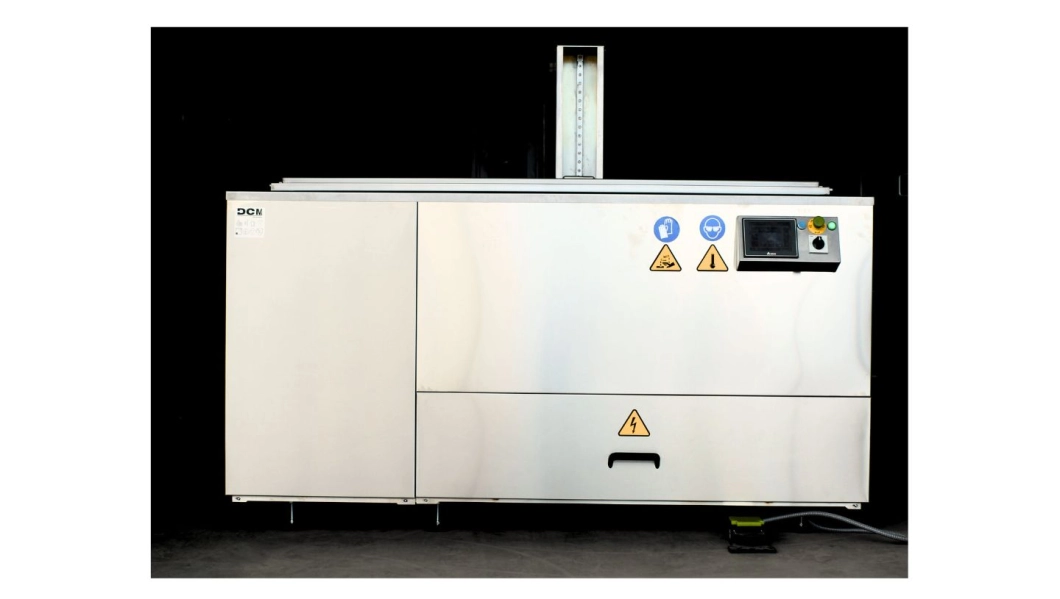

At DCM Ultrasonic, we have our own workshop where each and every part is manufactured and assembled. Furthermore, we are one of the few manufacturers with our own patented ultrasound technology that is 100% Spanish-made.

Industrial parts cleaning machines are designed to effectively remove any type of surface or embedded dirt from metal, plastic, or technical components. Using technologies such as ultrasound, these machines can clean every corner of a part without damaging it, quickly, and with reduced energy consumption.

In our case, we manufacture and develop ultrasonic cleaning machines adapted to the real needs of the productive sectors. We are not talking about a generic product, but rather specialized solutions for professionals who demand efficiency, robustness, and durability.

1. SL Range: Static Ultrasonic Cleaning

Our SL series is designed for cleaning delicate or tolerant parts that do not require movement during the process. These machines feature:

2. DL Range: Controlled Dynamic Loading

Dynamic loading optimizes cavitation, eliminating shadows and improving efficiency in complex geometries. Ultrasonic cleaning machines with dynamic loading represent an advanced solution for cleaning, degreasing, stripping, disinfecting, and descaling processes on a wide variety of materials, from metals to polymers and ceramics.

See DL Series

3. RL Range: Precise Rotary Loading

The RL line is designed for parts that require rotation during cleaning.

See RL Series

Interested in finding out which one best suits your process? Tell us the type of parts and volume you handle, and we'll design the perfect machine together.

News

Industrial Machines for Cleaning Parts

25 June de 2025

Machines for cleaning parts have become an essential tool for all types of industries that require their components to be kept free of contaminants, grease, metal residue, carbon, oxides, or chemical residues. From automotive workshops to power plants and naval facilities, having efficient cleaning equipment is no longer an option, but an operational necessity.At DCM Ultrasonic, we have our own workshop where each and every part is manufactured and assembled. Furthermore, we are one of the few manufacturers with our own patented ultrasound technology that is 100% Spanish-made.

Industrial parts cleaning machines are designed to effectively remove any type of surface or embedded dirt from metal, plastic, or technical components. Using technologies such as ultrasound, these machines can clean every corner of a part without damaging it, quickly, and with reduced energy consumption.

In our case, we manufacture and develop ultrasonic cleaning machines adapted to the real needs of the productive sectors. We are not talking about a generic product, but rather specialized solutions for professionals who demand efficiency, robustness, and durability.

Ranges of parts cleaning machines we offer

Each range caters to different part sizes, work volumes, and automation requirements. All DCM Ultrasonic ranges feature patented technology, are manufactured in our workshop (100% Spanish manufacturing), and are built with durable, high-quality materials.1. SL Range: Static Ultrasonic Cleaning

Our SL series is designed for cleaning delicate or tolerant parts that do not require movement during the process. These machines feature:

- Static load and removable platform (up to 3,000 kg).

- Synchronized digital generators (24–40 kHz) with high efficiency (approximately 98%).

- High-quality transducers (PZT4, Japan).

- Thermal and acoustic insulation (lower energy consumption)

- PLC/HMI control and Ethernet connection

2. DL Range: Controlled Dynamic Loading

Dynamic loading optimizes cavitation, eliminating shadows and improving efficiency in complex geometries. Ultrasonic cleaning machines with dynamic loading represent an advanced solution for cleaning, degreasing, stripping, disinfecting, and descaling processes on a wide variety of materials, from metals to polymers and ceramics.

- 100 to 9,000 L tanks.

- Pneumatic (up to 1,000 kg) or hydraulic (higher capacity) lifting.

- Oil separation system.

- Optional options: automatic lid, detergent dispenser, filtration, oil extraction, AISI 316 soundproofed steel.

See DL Series

3. RL Range: Precise Rotary Loading

The RL line is designed for parts that require rotation during cleaning.

- Simultaneous rotary and vertical movement.

- Ideal for anilox rollers, cylindrical parts, gears, and bearings.

- Capacity for up to 5 baskets simultaneously, handling loads of up to 500 kg.

- Electric heating elements on the sides.

- Integrated electrical panel.

See RL Series

Main advantages of our part cleaning machines.

- Consistent and repeatable results, without direct contact.

- Energy efficiency thanks to insulation and cycle optimization.

- Load versatility, depending on the type of part and process.

- Easy integration into manual or automated industrial lines.

- Hygienic and safe design, made of stainless steel (AISI 304L/316L).

- Traceability and control via PLC, HMI, and Ethernet.

Interested in finding out which one best suits your process? Tell us the type of parts and volume you handle, and we'll design the perfect machine together.