Tue, 01 Jul 2025 10:09:01 +0200

At DCM Ultrasonic, we specialize in the manufacture of ultrasonic cleaners with patented technology and 100% Spanish manufacturing. Ultrasonic cleaners for industrial on-site cleaning.

Ultrasonic baths are systems that use high-frequency sound waves, generated by piezoelectric transducers, which are transmitted through a cleaning fluid. These waves cause a physical phenomenon known as cavitation, where millions of microbubbles form and collapse, releasing enough energy to remove contaminants from surfaces without damaging them.

1. Deep and Uniform Cleaning

Thanks to cavitation, ultrasonic cleaners penetrate inaccessible areas such as threads, cavities, blind holes, or complex geometries, achieving uniform cleaning throughout the part.

2. Reduction in Cleaning Times

Cleaning cycles are fast, improving operational efficiency. In most cases, a result superior to that achieved by manual cleaning is achieved in just a few minutes.

3. Chemical and Water Savings

The use of harsh solvents and detergents is significantly reduced. In many cases, biodegradable aqueous solutions are sufficient, making ultrasonic cleaners a more environmentally friendly option.

4. Non-abrasive and Non-invasive

Unlike blasting or brushing, ultrasound does not wear or alter surfaces, even on delicate or high-value parts.

5. Automation and Repeatability

They allow for standardized, programmable, and repeatable processes, ensuring consistent quality and facilitating regulatory compliance in regulated industries.

See ultrasonic baths

Mechanical workshops and automotive

In the automotive and maintenance sectors, it is common to find parts covered in grease, carbon deposits, oil, rust, or sludge. Ultrasonic cleaners remove these residues from:

These sectors require precision cleaning for complex components with very high surface quality requirements. Ultrasound is ideal for:

Here, cleanliness is key to maintaining sterility and eliminating biofilms, viruses, and bacteria. It is used in:

Ultrasound gently cleans electronic boards, integrated circuits, microcomponents, and sensors without damaging them.

Hygiene and disinfection are mandatory. Ultrasonic cleaners can clean:

Thanks to their gentleness, ultrasonic cleaners remove dust, grease, waxes, and compounds without damaging:

Discover our ultrasonic bath rentals

At DCM Ultrasonic, we manufacture a wide range of ultrasonic cleaners, adapted to all types of sectors and needs:

LAB Range

Tabletop machines ideal for laboratories, small workshops, opticians, jewelry stores, precision electronics, and dentistry.

DL Range

Robust industrial machines for mechanical workshops, automotive, naval, and industrial maintenance. Available with heating, timers, filtration, and different power levels. Custom models available.

SL Range

Ultrasonic cleaners ideal for delicate parts and components that require a fixed position and zero movement.

Ultrasonic Flow Cells

Ultrasonic technology for liquid cleaning, degassing, homogenizing, or disinfecting fluids in closed lines. Applications in food, laboratory, bioenergy, and chemical processes.

Defoaming System

Prevents and eliminates foam in circuits, tanks, and production lines that use ultrasound or turbulent motion. Ideal for the beverage, pharmaceutical, and cosmetics industries.

Ultrasonic cleaners are a modern, effective, and sustainable solution for the technical cleaning of parts, tools, components, and liquids. In sectors where precision, hygiene, and efficiency are essential, this technology makes the difference.

At DCM Ultrasonic, we offer you the most complete range of equipment, from compact benchtop models to multi-stage industrial systems, tailored to each professional sector.

If you are looking for a solution to improve your cleaning process, reduce operating costs, and gain efficiency, do not hesitate to contact us. We will be happy to advise you!

News

Advantages of using ultrasonic baths in different industrial sectors

01 July de 2025

Ultrasonic baths have become essential tools for a wide variety of industries. This advanced technology allows for the removal of all types of dirt, grease, rust, dust particles, machining residue, and other contaminants, even in areas inaccessible using manual or traditional cleaning methods.At DCM Ultrasonic, we specialize in the manufacture of ultrasonic cleaners with patented technology and 100% Spanish manufacturing. Ultrasonic cleaners for industrial on-site cleaning.

Ultrasonic baths are systems that use high-frequency sound waves, generated by piezoelectric transducers, which are transmitted through a cleaning fluid. These waves cause a physical phenomenon known as cavitation, where millions of microbubbles form and collapse, releasing enough energy to remove contaminants from surfaces without damaging them.

General Advantages of Ultrasonic Baths

1. Deep and Uniform Cleaning

Thanks to cavitation, ultrasonic cleaners penetrate inaccessible areas such as threads, cavities, blind holes, or complex geometries, achieving uniform cleaning throughout the part.

2. Reduction in Cleaning Times

Cleaning cycles are fast, improving operational efficiency. In most cases, a result superior to that achieved by manual cleaning is achieved in just a few minutes.

3. Chemical and Water Savings

The use of harsh solvents and detergents is significantly reduced. In many cases, biodegradable aqueous solutions are sufficient, making ultrasonic cleaners a more environmentally friendly option.

4. Non-abrasive and Non-invasive

Unlike blasting or brushing, ultrasound does not wear or alter surfaces, even on delicate or high-value parts.

5. Automation and Repeatability

They allow for standardized, programmable, and repeatable processes, ensuring consistent quality and facilitating regulatory compliance in regulated industries.

See ultrasonic baths

Industrial sectors where ultrasonic baths add value

Mechanical workshops and automotive

In the automotive and maintenance sectors, it is common to find parts covered in grease, carbon deposits, oil, rust, or sludge. Ultrasonic cleaners remove these residues from:

- Turbos and cylinder heads

- Injectors and valves

- Carburetors and filters

- Pistons, connecting rods, axles, seals

These sectors require precision cleaning for complex components with very high surface quality requirements. Ultrasound is ideal for:

- Cleaning hydraulic components

- Instrumentation and sensors

- Precision assemblies

Here, cleanliness is key to maintaining sterility and eliminating biofilms, viruses, and bacteria. It is used in:

- Surgical and dental instruments

- Pharmaceutical manufacturing molds

- Laboratory glassware

Ultrasound gently cleans electronic boards, integrated circuits, microcomponents, and sensors without damaging them.

- Removing solder and flux residue

- Pre-coating cleaning

- Maintenance of used boards

Hygiene and disinfection are mandatory. Ultrasonic cleaners can clean:

- Molds and tooling

- Nozzles and valves

- Bottling line components

Thanks to their gentleness, ultrasonic cleaners remove dust, grease, waxes, and compounds without damaging:

- Brass, gold, steel, or titanium parts

- Optical lenses and eyeglasses

- Fine watch parts

Discover our ultrasonic bath rentals

DCM Ultrasonic Ultrasonic Cleaner Models

At DCM Ultrasonic, we manufacture a wide range of ultrasonic cleaners, adapted to all types of sectors and needs:LAB Range

Tabletop machines ideal for laboratories, small workshops, opticians, jewelry stores, precision electronics, and dentistry.

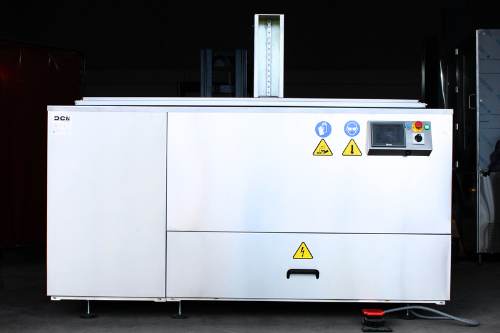

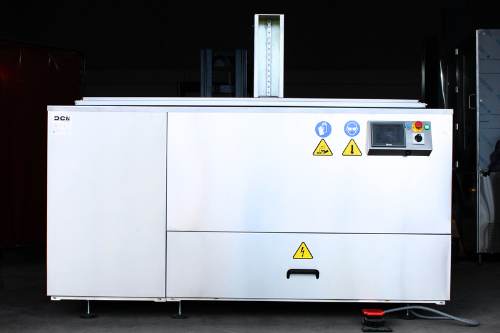

DL Range

Robust industrial machines for mechanical workshops, automotive, naval, and industrial maintenance. Available with heating, timers, filtration, and different power levels. Custom models available.

SL Range

Ultrasonic cleaners ideal for delicate parts and components that require a fixed position and zero movement.

Ultrasonic Flow Cells

Ultrasonic technology for liquid cleaning, degassing, homogenizing, or disinfecting fluids in closed lines. Applications in food, laboratory, bioenergy, and chemical processes.

Defoaming System

Prevents and eliminates foam in circuits, tanks, and production lines that use ultrasound or turbulent motion. Ideal for the beverage, pharmaceutical, and cosmetics industries.

Ultrasonic cleaners are a modern, effective, and sustainable solution for the technical cleaning of parts, tools, components, and liquids. In sectors where precision, hygiene, and efficiency are essential, this technology makes the difference.

At DCM Ultrasonic, we offer you the most complete range of equipment, from compact benchtop models to multi-stage industrial systems, tailored to each professional sector.

If you are looking for a solution to improve your cleaning process, reduce operating costs, and gain efficiency, do not hesitate to contact us. We will be happy to advise you!