Mon, 25 Aug 2025 09:38:48 +0200

Currently, the cleaning methods used in this sector include manual cleaning, chemical cleaning, and blast cleaning. Although effective in some cases, they have significant limitations: high consumption of aggressive chemicals, risk of surface damage, long downtime, and inconsistent efficiency when reaching hard-to-reach areas. Faced with this scenario, ultrasonic cleaning has emerged as a cutting-edge technology that is transforming industrial maintenance in the energy sector.

Ultrasonic technology is based on the generation of high-frequency sound waves within a fluid. These waves produce the phenomenon of controlled cavitation: millions of microbubbles that collapse instantly, generating localized energy capable of removing dirt, scale, oils, grease, and oxides, without damaging the surfaces of the treated material.

In the oil and gas sector, this technique offers competitive advantages that surpass conventional methods:

Our cleaning solution for the oil and gas sector

Heat exchangers are essential elements in refineries, processing plants, and offshore platforms. However, they are also one of the most susceptible equipment to fouling and organic and inorganic deposits.

Fouling significantly reduces thermal efficiency, increases energy costs, and requires unscheduled maintenance shutdowns. Ultrasonic cleaning has established itself as the best alternative to mechanical and chemical systems for several reasons:

Compared to chemical cleaning, ultrasound significantly reduces the environmental footprint and the need for hazardous waste disposal. Compared to manual cleaning, it eliminates human error and the risks associated with mechanical handling. And compared to high-pressure water jets, it offers a less aggressive treatment that prevents material wear.

In short, it is a method that combines efficiency, safety, and sustainability, three key pillars in the energy industry's evolution toward more responsible and profitable models.

Cleaning for the Petrochemical Industry

At DCM Ultrasonic, we design and manufacture ultrasonic cleaning machines tailored to the demands of the oil and gas sector. From high-capacity tanks for cleaning heat exchangers to customized systems for valves, filters, or complex components, our solutions are designed to maximize operational efficiency and reduce maintenance costs.

Our equipment allows ultrasonic cleaning to be integrated into preventive and corrective maintenance processes, offering fast, safe, and repeatable work cycles, with the guarantee of superior results compared to traditional methods.

Cleaning in the oil and gas sector is evolving toward more efficient and sustainable technologies. Ultrasonic cleaning today represents the most advanced solution for the maintenance of heat exchangers and multiple critical components, combining technical performance, occupational safety, and environmental friendliness.

News

Cleaning of exchangers and other components of the petrochemical industry

25 August de 2025

Among the most critical tasks in the petrochemical industry is the cleaning of heat exchangers, pumps, valves, pipes, and multiple components subjected to extreme conditions of pressure, temperature, and exposure to hydrocarbons. Cleaning for the oil and gas sector with ultrasonic machines.Currently, the cleaning methods used in this sector include manual cleaning, chemical cleaning, and blast cleaning. Although effective in some cases, they have significant limitations: high consumption of aggressive chemicals, risk of surface damage, long downtime, and inconsistent efficiency when reaching hard-to-reach areas. Faced with this scenario, ultrasonic cleaning has emerged as a cutting-edge technology that is transforming industrial maintenance in the energy sector.

Why choose ultrasonic cleaning in oil and gas?

Ultrasonic technology is based on the generation of high-frequency sound waves within a fluid. These waves produce the phenomenon of controlled cavitation: millions of microbubbles that collapse instantly, generating localized energy capable of removing dirt, scale, oils, grease, and oxides, without damaging the surfaces of the treated material.In the oil and gas sector, this technique offers competitive advantages that surpass conventional methods:

- Deep and homogeneous cleaning, even in cavities, crevices, or internal areas inaccessible to hand tools.

- Reduced downtime, with cleaning cycles much faster than traditional methods.

- Sustainability, by reducing the use of aggressive chemicals and reducing water consumption.

- Increased safety, as it eliminates worker exposure to toxic solvents and aggressive mechanical processes.

- Protection of the integrity of the parts, as it is a non-abrasive process.

Our cleaning solution for the oil and gas sector

Ultrasonic heat exchanger cleaning

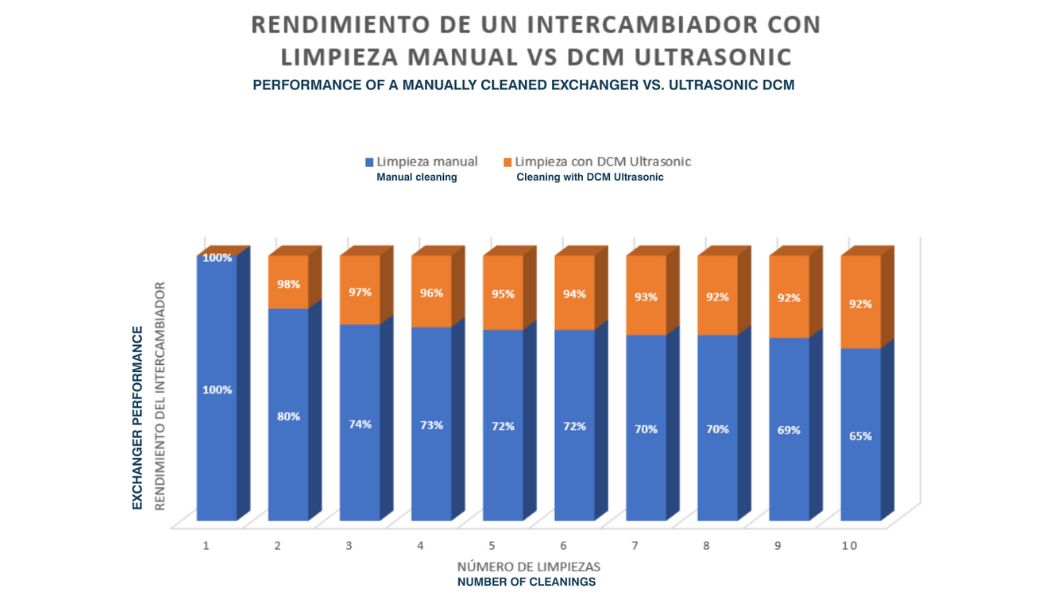

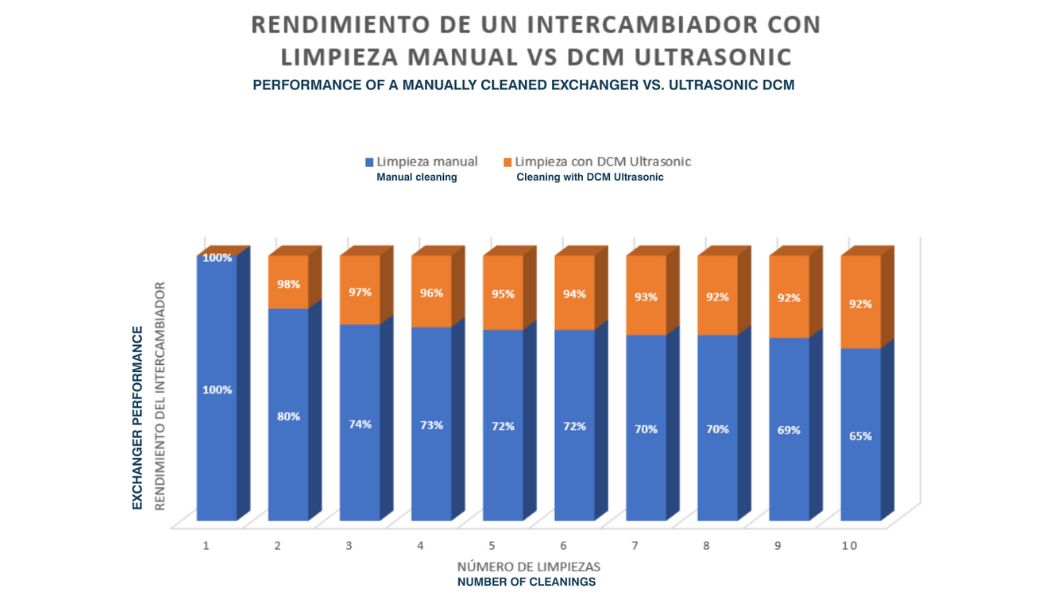

Heat exchangers are essential elements in refineries, processing plants, and offshore platforms. However, they are also one of the most susceptible equipment to fouling and organic and inorganic deposits.Fouling significantly reduces thermal efficiency, increases energy costs, and requires unscheduled maintenance shutdowns. Ultrasonic cleaning has established itself as the best alternative to mechanical and chemical systems for several reasons:

- Full access to internal ducts: Ultrasound removes deposits even in areas where physical access is impossible.

- Greater thermal efficiency recovery, extending the equipment's lifespan.

- Dramatically reduced cleaning times, with consistent and repeatable results.

- Respect for the geometry of the equipment, avoiding deformations or damage that abrasive methods can cause.

Comparison with Conventional Methods

Compared to chemical cleaning, ultrasound significantly reduces the environmental footprint and the need for hazardous waste disposal. Compared to manual cleaning, it eliminates human error and the risks associated with mechanical handling. And compared to high-pressure water jets, it offers a less aggressive treatment that prevents material wear.In short, it is a method that combines efficiency, safety, and sustainability, three key pillars in the energy industry's evolution toward more responsible and profitable models.

Other key components that benefit from ultrasonic cleaning

While heat exchangers are a priority, they are not the only critical equipment in the oil and gas sector that benefits from ultrasound. Other examples include:- Control and safety valves: free of deposits and residues that compromise their proper functioning.

- Pumps and hydraulic components: cleaning of oil, grease, and sludge residues without complex disassembly.

- Metal and mesh filters: removal of solid particles that block flow.

- Small-diameter pipes and elbows: restoration of original flow without resorting to highly corrosive chemicals.

- Maintenance tools and fixtures: ready for immediate reuse without premature wear.

Cleaning for the Petrochemical Industry

DCM Ultrasonic: Ultrasonic Solutions for the Oil and Gas Sector

At DCM Ultrasonic, we design and manufacture ultrasonic cleaning machines tailored to the demands of the oil and gas sector. From high-capacity tanks for cleaning heat exchangers to customized systems for valves, filters, or complex components, our solutions are designed to maximize operational efficiency and reduce maintenance costs.Our equipment allows ultrasonic cleaning to be integrated into preventive and corrective maintenance processes, offering fast, safe, and repeatable work cycles, with the guarantee of superior results compared to traditional methods.

Cleaning in the oil and gas sector is evolving toward more efficient and sustainable technologies. Ultrasonic cleaning today represents the most advanced solution for the maintenance of heat exchangers and multiple critical components, combining technical performance, occupational safety, and environmental friendliness.