Tue, 21 Oct 2025 10:40:58 +0200

Ultrasonic cleaning represents a technological revolution in the way companies approach the maintenance and cleaning of their components. At DCM Ultrasonic, we have spent years developing systems that harness the phenomenon of controlled cavitation, offering more consistent, faster and sustainable results.

Ultrasonic technology uses high-frequency sound waves (20–120 kHz) that are transmitted through a liquid. These waves generate millions of microbubbles that implode in a controlled manner, releasing energy and causing a micro-impact effect on surfaces.

This phenomenon, known as cavitation, removes particles of dirt, grease, oxides and machining residues even in internal geometries or inaccessible cavities, without damaging the base material. The result is uniform, thorough and repeatable cleaning.

It is important to note that the effectiveness of ultrasonic cleaning depends on factors such as the ultrasonic frequency, the temperature of the cleaning liquid and the appropriate choice of cleaning solution. It is therefore essential to follow the manufacturer's recommendations and adapt the process to specific cleaning requirements.

1. Drastic reduction in cleaning time

One of the most notable benefits is the speed of the process. Ultrasound acts simultaneously on the entire submerged surface, eliminating the need for manual brushing or prolonged soaking.

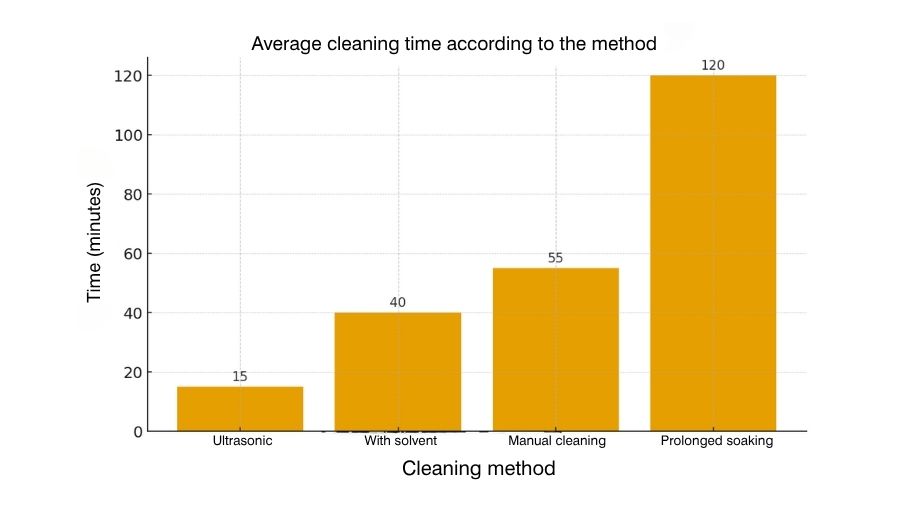

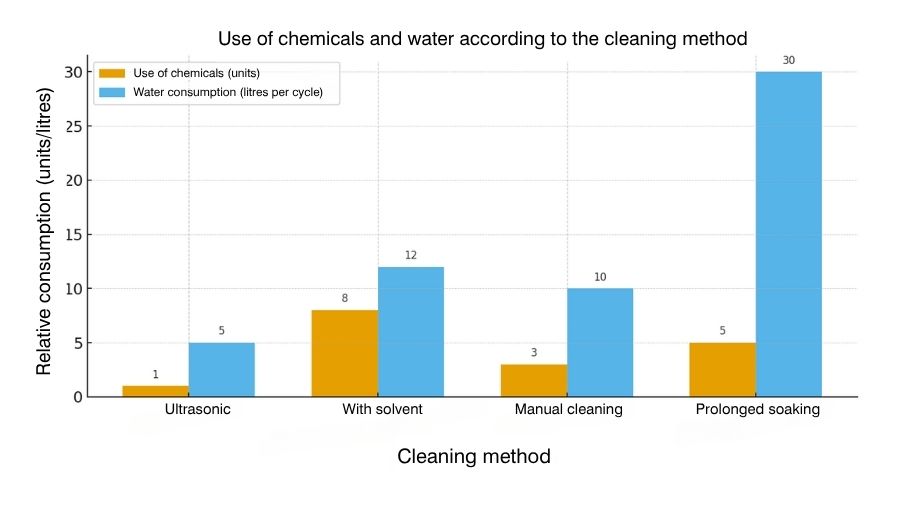

The following chart compares the average times for different industrial methods:

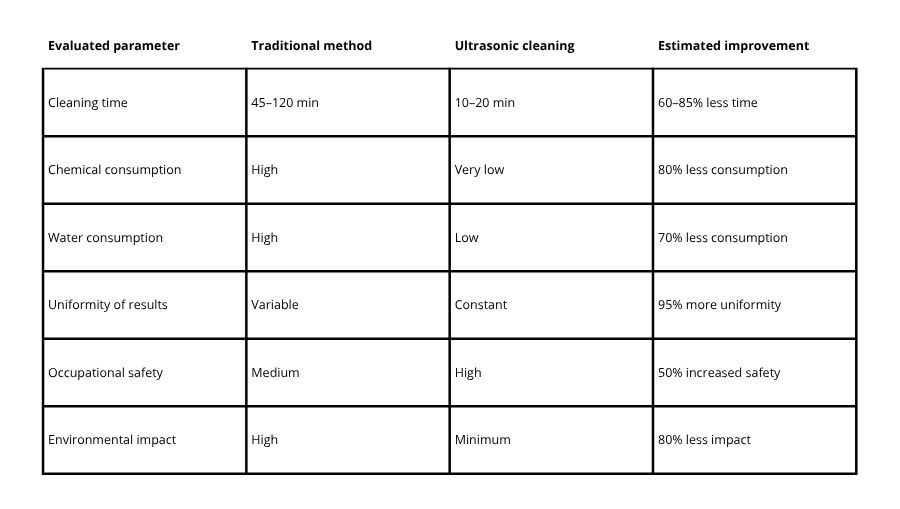

Ultrasonic cleaning can reduce operating times by between 60% and 85%, which translates into higher productivity and lower energy consumption per batch.

2. Deep cleaning in inaccessible areas

Ultrasonic cavitation acts in every corner of the bath, even inside channels, holes, threads, heat exchangers, carburettors, or complex moulds. While a brush or pressure jet cannot reach certain internal areas, cavitation microbubbles can, ensuring complete and uniform cleaning.

This makes ultrasonic technology a key tool for sectors such as:

3. Savings in chemicals and water consumption

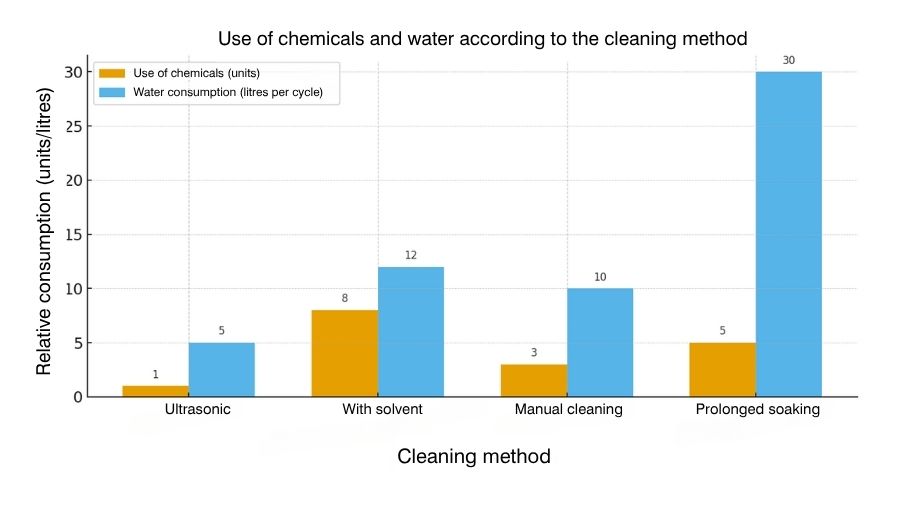

Most traditional methods rely on the use of aggressive solvents or detergents, which increases costs and environmental impact. With ultrasonics, it is possible to work with biodegradable detergents and much lower concentrations, as cavitation takes care of the mechanical action.

Ultrasonic cleaning reduces chemical consumption by up to 80%. Water usage can be reduced by more than 70% thanks to the bath's filtration and recirculation systems. This not only means operational savings, but also a reduction in environmental impact and waste generated.

4. Greater repeatability and process control

Unlike manual brushing or uncontrolled immersion, DCM Ultrasonic equipment allows you to set parameters for:

5. Improved safety and ergonomics

Reducing direct contact with aggressive chemicals or contaminated parts means greater safety for operators and fewer risks of injury or poisoning. Furthermore, as manual scrubbing is not required, physical strain is avoided and human error is minimised.

Ultrasonic cleaning is not only a modern alternative, but a complete solution for industrial efficiency.

It offers a triple benefit:

News

Advantages of ultrasonic cleaning over traditional methods

21 October de 2025

Industrial cleaning processes have relied on the use of solvents, manual brushing, or prolonged chemical baths. However, these methods have significant limitations: long cycle times, high chemical consumption, variability of results and risks to health and the environment.Ultrasonic cleaning represents a technological revolution in the way companies approach the maintenance and cleaning of their components. At DCM Ultrasonic, we have spent years developing systems that harness the phenomenon of controlled cavitation, offering more consistent, faster and sustainable results.

How does ultrasonic cleaning work?

Ultrasonic technology uses high-frequency sound waves (20–120 kHz) that are transmitted through a liquid. These waves generate millions of microbubbles that implode in a controlled manner, releasing energy and causing a micro-impact effect on surfaces.This phenomenon, known as cavitation, removes particles of dirt, grease, oxides and machining residues even in internal geometries or inaccessible cavities, without damaging the base material. The result is uniform, thorough and repeatable cleaning.

It is important to note that the effectiveness of ultrasonic cleaning depends on factors such as the ultrasonic frequency, the temperature of the cleaning liquid and the appropriate choice of cleaning solution. It is therefore essential to follow the manufacturer's recommendations and adapt the process to specific cleaning requirements.

Ventajas de la limpieza ultrasónica frente a métodos tradicionales

1. Drastic reduction in cleaning time

One of the most notable benefits is the speed of the process. Ultrasound acts simultaneously on the entire submerged surface, eliminating the need for manual brushing or prolonged soaking.

The following chart compares the average times for different industrial methods:

Ultrasonic cleaning can reduce operating times by between 60% and 85%, which translates into higher productivity and lower energy consumption per batch.

2. Deep cleaning in inaccessible areas

Ultrasonic cavitation acts in every corner of the bath, even inside channels, holes, threads, heat exchangers, carburettors, or complex moulds. While a brush or pressure jet cannot reach certain internal areas, cavitation microbubbles can, ensuring complete and uniform cleaning.

This makes ultrasonic technology a key tool for sectors such as:

- Aeronautics and aerospace: where precision cleaning without abrasion is required.

- Medical and pharmaceutical: in the decontamination of stainless steel instruments and components.

- Automotive: for cleaning injectors, cylinder heads, valves and fuel systems.

- Energy and naval: in the maintenance of exchangers, radiators or metal filters.

3. Savings in chemicals and water consumption

Most traditional methods rely on the use of aggressive solvents or detergents, which increases costs and environmental impact. With ultrasonics, it is possible to work with biodegradable detergents and much lower concentrations, as cavitation takes care of the mechanical action.

Ultrasonic cleaning reduces chemical consumption by up to 80%. Water usage can be reduced by more than 70% thanks to the bath's filtration and recirculation systems. This not only means operational savings, but also a reduction in environmental impact and waste generated.

4. Greater repeatability and process control

Unlike manual brushing or uncontrolled immersion, DCM Ultrasonic equipment allows you to set parameters for:

- Ultrasound frequency according to the type of dirt.

- Exposure time and bath temperature.

- Automatic filtration and recirculation systems.

5. Improved safety and ergonomics

Reducing direct contact with aggressive chemicals or contaminated parts means greater safety for operators and fewer risks of injury or poisoning. Furthermore, as manual scrubbing is not required, physical strain is avoided and human error is minimised.

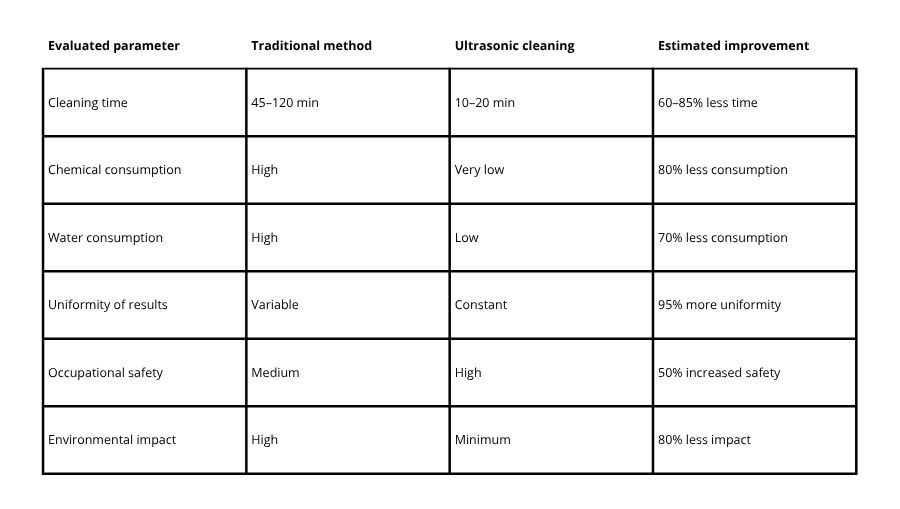

Quantifiable benefits and return on investment (ROI)

- Ultrasonic cleaning reduces downtime and cleaning time.

- Ultrasonic cleaning reduces downtime and cleaning time.

- Less chemical consumption during the cleaning process.

- Ultrasonic cleaning offers better results and greater uniformity in cleaning.

- Operator safety is guaranteed throughout the cleaning process.

- It has a lower environmental impact by saving 80% more water than other processes.

Cost-effective, clean and future-proof technology

Ultrasonic cleaning is not only a modern alternative, but a complete solution for industrial efficiency.It offers a triple benefit:

- Higher productivity and quality.

- Lower operating costs.

- A genuine commitment to the environment.