Mon, 22 Apr 2024 17:21:09 +0200

Degassing the bath means eliminating all the air dissolved in the bath. Ultrasonics are most effective when the bath is degassed. As long as there is air dissolved in the bath, all the ultrasonic power is used to eliminate this air in solution and not to make it fit. the liquid. For a unit of about 700 liters, it takes an average of 4 hours to degas the bath.

1. Using inappropriate detergents.

2. Operating the machine with too low or too high a liquid level.

3. Overloading the cleaning basket.

4. Using incorrect temperatures.

5. Lack of equipment maintenance.

If you have problems with your ultrasonic machine, we will help you, no matter what brand it is.

1. Proper Cavitation Generation

Cavitation is the heart of the ultrasonic cleaning process. If your machine is working properly, it should produce visible bubbles in the cleaning liquid and generate a characteristic high-frequency sound.

2. Stable Ultrasonic Frequency

Frequencies must be kept within the range specified for each application. A generator in poor condition could produce an unstable frequency, which affects cleaning efficiency.

3. Uniformity in Cleaning

If you notice that parts are not cleaned evenly, there could be an uneven distribution of ultrasound or a problem with the transducers.

4. Operation of the Ultrasonic Generator

The generator must emit a constant signal without interruptions or sudden variations in power. If the generator fails, cleaning will be affected.

5. Cleaning Bath Temperature

The liquid must reach and maintain the recommended temperature for each application. An incorrect temperature reduces the effectiveness of the process.

6. Liquid Levels in the Tank

The liquid level must be within the indicated values. A level that is too low or too high could reduce the effectiveness of the ultrasound and cause damage to the transducers.

7. Condition of the Transducers

The transducers must be in good condition, without cracks or detachments. If a transducer is defective, the cleaning power will be affected.

8. Presence of Excessive Foam or Bubbles

Excessive foam could indicate contamination of the liquid or incorrect use of the detergent. This affects the efficiency of the cavitation.

9. Cleaning Time According to Specifications

If the parts take longer than normal to clean, there could be a loss of power in the ultrasound or a problem with the detergent used.

10. Normal Noise and Vibration

Excessive noise or abnormal vibrations can be a sign of malfunction. Ultrasonic machines should operate with a stable hum and no intermittent or strange noises.

Checking these 10 key points will help ensure that your ultrasonic cleaning machine is working properly, optimizing its performance and prolonging its lifespan.

News

How do I know if my ultrasonic cleaning equipment is working properly?

22 April de 2024

Ultrasound cleaning equipment uses the cavitation phenomenon to remove traces of dirt from the surface of the part to be cleaned, therefore, to obtain a good cleaning result, it is essential to have good cavitation.

Cavitation depends fundamentally on:

Cavitation depends fundamentally on:

- The temperature of the liquid.

- The surface tension.

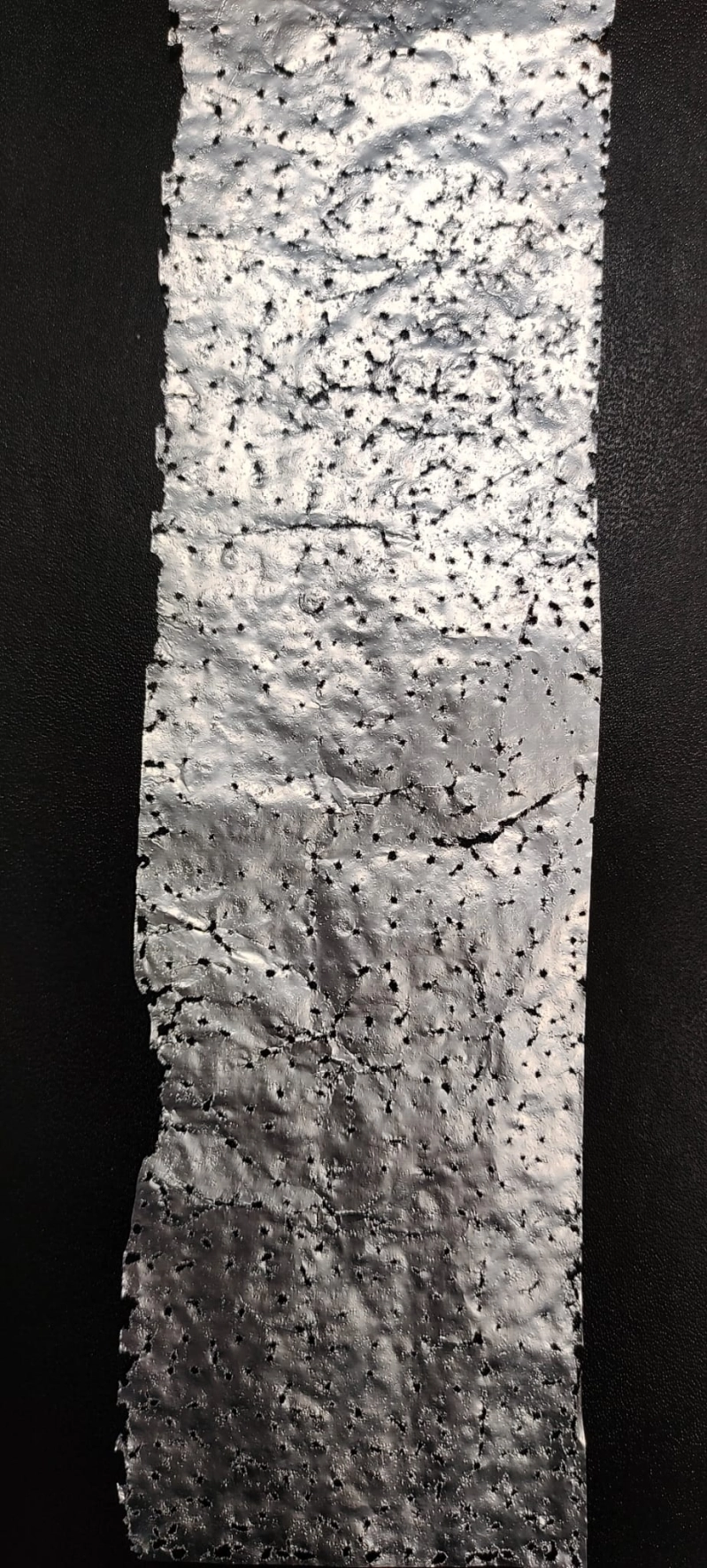

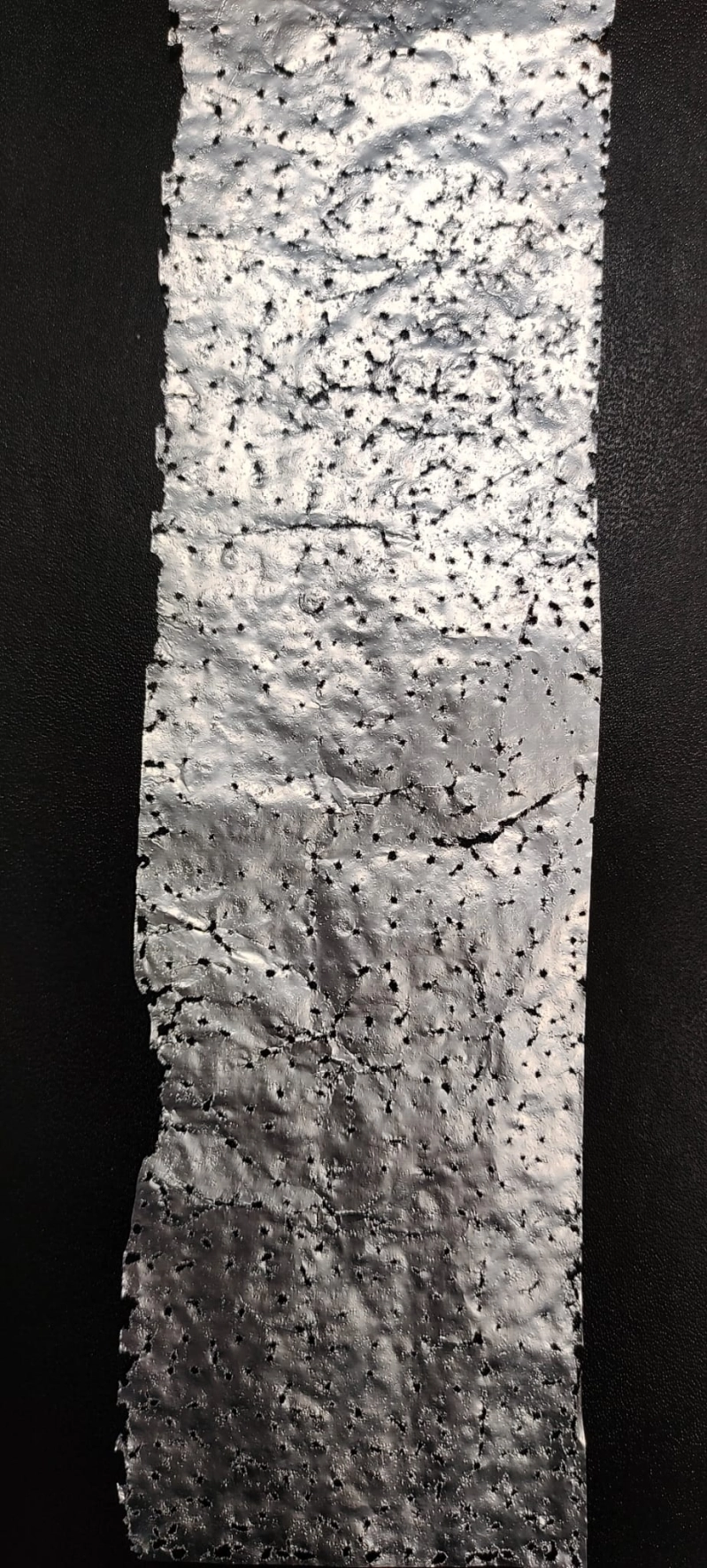

It is important to perform a cavitation test to check the correct state of the bath. To do this, we will use a sheet of aluminum foil about 200mm long and 50mm wide that we will immerse in the bath with the ultrasound turned on at maximum power for about 30 seconds. If the result is good, we should obtain an image like the one in the sample. The absence of these small holes will denote that we do not have cavitation in the bathroom, so the results obtained in cleaning will not be favorable. On the contrary, if we obtain a sample with holes but they are large and poorly distributed, it will mean that we do have room but The bathroom conditions are not ideal.

To perform this test, it is recommended to have a temperature between 60ºC and 70ºC and to have degassed the bath.

To perform this test, it is recommended to have a temperature between 60ºC and 70ºC and to have degassed the bath.

What does it mean to degas the bath?

Degassing the bath means eliminating all the air dissolved in the bath. Ultrasonics are most effective when the bath is degassed. As long as there is air dissolved in the bath, all the ultrasonic power is used to eliminate this air in solution and not to make it fit. the liquid. For a unit of about 700 liters, it takes an average of 4 hours to degas the bath.

5 common errors due to the misuse of an ultrasonic cleaning machine:

1. Using inappropriate detergents.

2. Operating the machine with too low or too high a liquid level.

3. Overloading the cleaning basket.

4. Using incorrect temperatures.

5. Lack of equipment maintenance.

If you have problems with your ultrasonic machine, we will help you, no matter what brand it is.

10 Key Points to Know if Your Ultrasonic Machine is Working Properly

1. Proper Cavitation Generation

Cavitation is the heart of the ultrasonic cleaning process. If your machine is working properly, it should produce visible bubbles in the cleaning liquid and generate a characteristic high-frequency sound.

2. Stable Ultrasonic Frequency

Frequencies must be kept within the range specified for each application. A generator in poor condition could produce an unstable frequency, which affects cleaning efficiency.

3. Uniformity in Cleaning

If you notice that parts are not cleaned evenly, there could be an uneven distribution of ultrasound or a problem with the transducers.

4. Operation of the Ultrasonic Generator

The generator must emit a constant signal without interruptions or sudden variations in power. If the generator fails, cleaning will be affected.

5. Cleaning Bath Temperature

The liquid must reach and maintain the recommended temperature for each application. An incorrect temperature reduces the effectiveness of the process.

6. Liquid Levels in the Tank

The liquid level must be within the indicated values. A level that is too low or too high could reduce the effectiveness of the ultrasound and cause damage to the transducers.

7. Condition of the Transducers

The transducers must be in good condition, without cracks or detachments. If a transducer is defective, the cleaning power will be affected.

8. Presence of Excessive Foam or Bubbles

Excessive foam could indicate contamination of the liquid or incorrect use of the detergent. This affects the efficiency of the cavitation.

9. Cleaning Time According to Specifications

If the parts take longer than normal to clean, there could be a loss of power in the ultrasound or a problem with the detergent used.

10. Normal Noise and Vibration

Excessive noise or abnormal vibrations can be a sign of malfunction. Ultrasonic machines should operate with a stable hum and no intermittent or strange noises.

Checking these 10 key points will help ensure that your ultrasonic cleaning machine is working properly, optimizing its performance and prolonging its lifespan.