Tue, 10 Jun 2025 15:52:21 +0200

Ultrasonic cleaning of circuit boards and components has established itself as an ideal solution for keeping circuits in perfect condition without compromising their integrity. Ultrasonic technology uses high-frequency acoustic waves (usually between 25 and 100 kHz) to generate a phenomenon called cavitation. This phenomenon creates millions of microbubbles in the cleaning fluid, which collapse forcefully upon contact with the object's surface, loosening dirt even in microscopic or hard-to-reach areas.

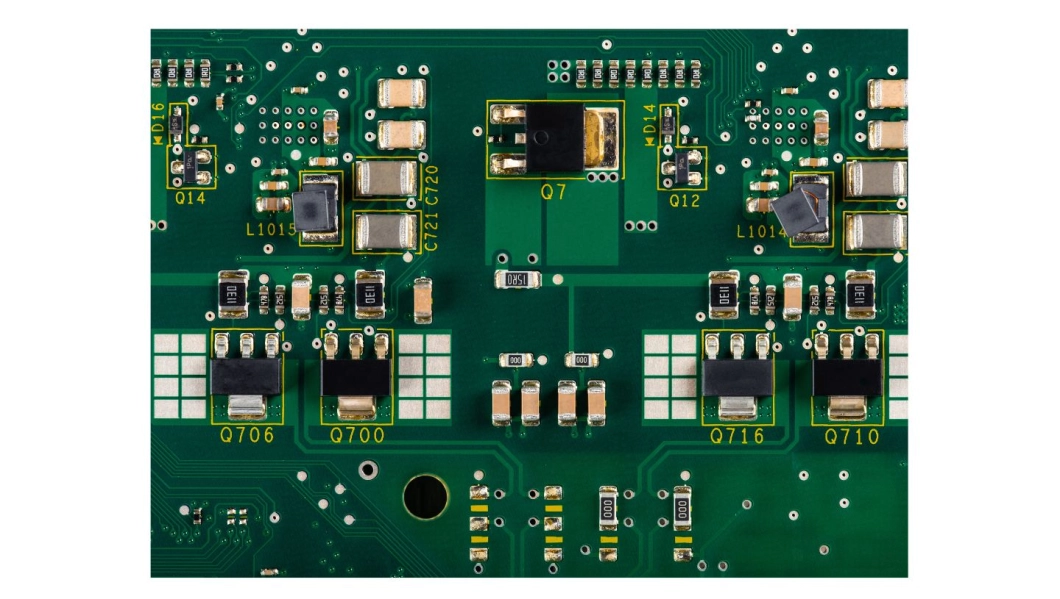

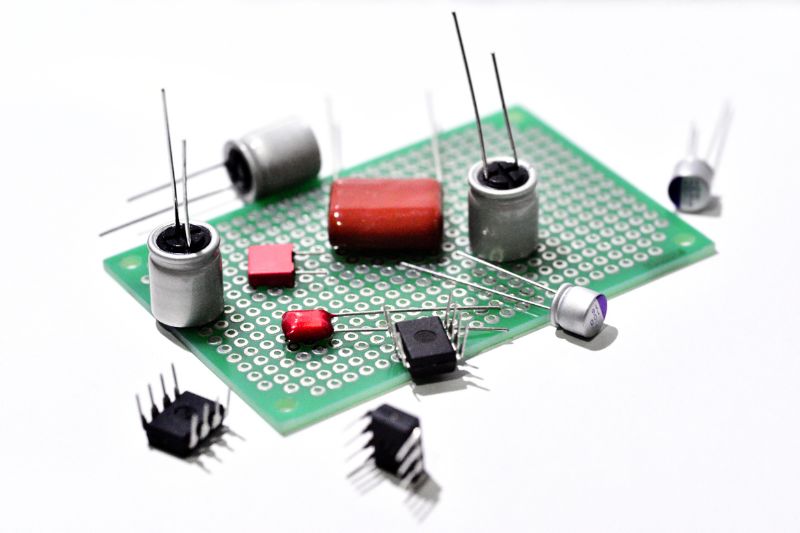

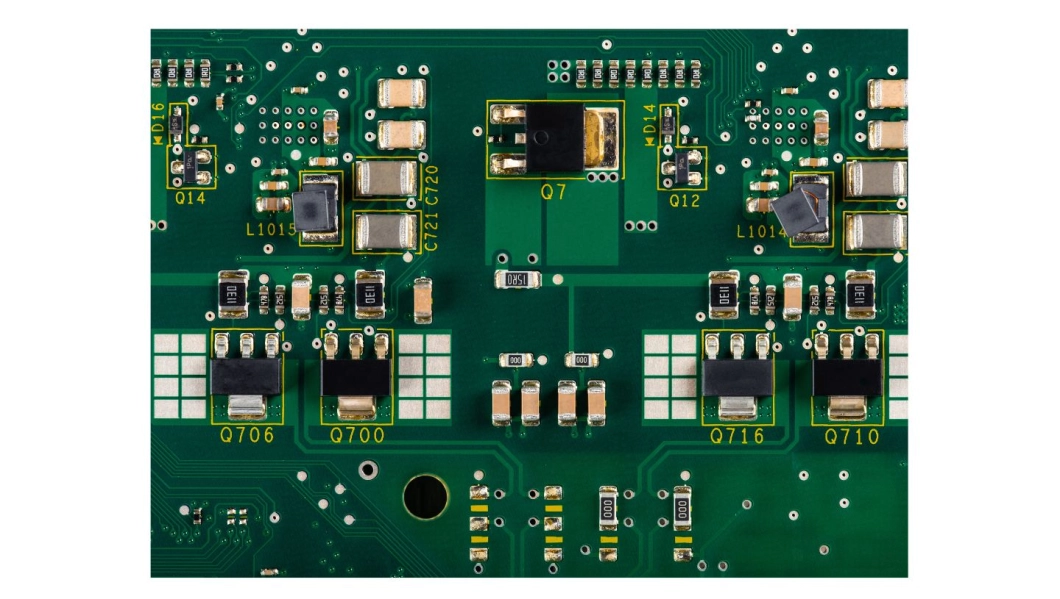

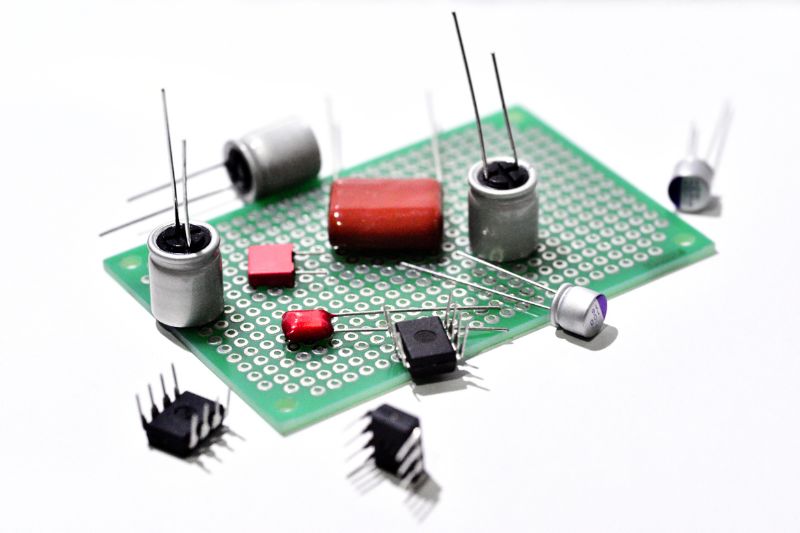

In the case of circuit boards, this process is powerful enough to remove embedded contaminants, but also gentle enough to avoid damaging sensitive components such as microchips, SMD solder, or copper traces. When the cleaning process is complete, the electronic components and boards must be dried to avoid corrosion or short circuits.

1. Deep and Uniform Cleaning

Unlike manual or spray methods, ultrasound reaches every corner, even under surface-mounted components, areas with high circuit density, or gaps that are otherwise impossible to reach.

2. Does Not Damage Components

When the proper parameters (frequency, time, temperature, and detergent) are applied, the process is 100% safe for the boards and their components. Ultrasonic vibrations do not exert direct mechanical pressure.

3. Eliminates all types of residue

This technology removes solder fluxes, rosin residue, oils, dust, metal particles, adhesive residue, and even organic contaminants such as grease and moisture.

4. Saves time and resources

Cleaning cycles are automated, fast, and reproducible. Multiple boards can be cleaned simultaneously, with less chemical consumption and less human effort.

5. Improved electronic performance

A residue-free PCB improves heat dissipation, reduces errors, and prevents electrical failures. This translates into a longer lifespan and more stable operation.

MACHINES FOR CLEANING ELECTRONIC BOARDS AND ELECTRONIC COMPONENTS

Ultrasonic cleaning of electronic boards is widely used in:

We offer configurations adapted for both small series and large production volumes, integrating filtration systems, temperature control, and adjustable timers that facilitate operations in laboratories, electronic assembly lines, or industrial maintenance centers. With our solutions, we guarantee deep, fast, and circuit-safe cleaning.

REQUEST MORE INFORMATION ABOUT OUR MACHINES

Although the technology is highly efficient, there are certain critical factors that must be taken into account to ensure the best results:

News

Cleaning electronic parts and circuit boards with an ultrasonic bath

10 June de 2025

Ultrasonic cleaning of electronic boards has become one of the most effective and safe solutions for removing residue, oxides, flux, and microscopic dirt without damaging sensitive components. In this article, we explain how it works, what advantages it offers, and why more and more companies are turning to this technology.Ultrasonic cleaning of circuit boards and components has established itself as an ideal solution for keeping circuits in perfect condition without compromising their integrity. Ultrasonic technology uses high-frequency acoustic waves (usually between 25 and 100 kHz) to generate a phenomenon called cavitation. This phenomenon creates millions of microbubbles in the cleaning fluid, which collapse forcefully upon contact with the object's surface, loosening dirt even in microscopic or hard-to-reach areas.

In the case of circuit boards, this process is powerful enough to remove embedded contaminants, but also gentle enough to avoid damaging sensitive components such as microchips, SMD solder, or copper traces. When the cleaning process is complete, the electronic components and boards must be dried to avoid corrosion or short circuits.

Advantages of Ultrasonic Cleaning for circuit board

1. Deep and Uniform Cleaning

Unlike manual or spray methods, ultrasound reaches every corner, even under surface-mounted components, areas with high circuit density, or gaps that are otherwise impossible to reach.

2. Does Not Damage Components

When the proper parameters (frequency, time, temperature, and detergent) are applied, the process is 100% safe for the boards and their components. Ultrasonic vibrations do not exert direct mechanical pressure.

3. Eliminates all types of residue

This technology removes solder fluxes, rosin residue, oils, dust, metal particles, adhesive residue, and even organic contaminants such as grease and moisture.

4. Saves time and resources

Cleaning cycles are automated, fast, and reproducible. Multiple boards can be cleaned simultaneously, with less chemical consumption and less human effort.

5. Improved electronic performance

A residue-free PCB improves heat dissipation, reduces errors, and prevents electrical failures. This translates into a longer lifespan and more stable operation.

MACHINES FOR CLEANING ELECTRONIC BOARDS AND ELECTRONIC COMPONENTS

Industrial applications - Electronic cleaning and circuit maintenance

Ultrasonic cleaning of electronic boards is widely used in:

- Electronic repair centers and technical laboratories.

- Automotive industry (ECUs, control units, sensors, electronic modules).

- Electronic device manufacturing (prior to encapsulation or testing).

- Aeronautical and railway maintenance.

- Medical electronics (diagnostic instruments, medical device PCBs).

- Defense and telecommunications equipment.

We offer configurations adapted for both small series and large production volumes, integrating filtration systems, temperature control, and adjustable timers that facilitate operations in laboratories, electronic assembly lines, or industrial maintenance centers. With our solutions, we guarantee deep, fast, and circuit-safe cleaning.

REQUEST MORE INFORMATION ABOUT OUR MACHINES

What to consider when using ultrasound on electronic boards?

The electronic board and components are placed inside the ultrasonic tank. Here, the parts are submerged under water/liquid, where the transducers emit high-frequency sound waves that generate millions of tiny bubbles. These bubbles undergo a phenomenon called cavitation, where they collapse and release energy in the form of microscopic explosions. These explosions provide intensive cleaning action, penetrating even hard-to-reach areas and removing particles that might have resisted conventional methods.Although the technology is highly efficient, there are certain critical factors that must be taken into account to ensure the best results:

- Selecting the right detergent: Specific solutions for electronics, chloride-free and with a controlled pH, must be used.

- Recommended frequency: For delicate components, the frequency range is usually between 35 and 80 kHz.

- Exposure time: Generally between 2 and 10 minutes, depending on the degree of soiling.

- It is essential to ensure complete drying to prevent moisture retention, especially in connectors or sockets.